the shore. Another advantage of such wells is that they can be constructed above the shoreline under

overhead concealment. Other types such as driven and jetted wellpoints may also be effective at sandy

beach locations.

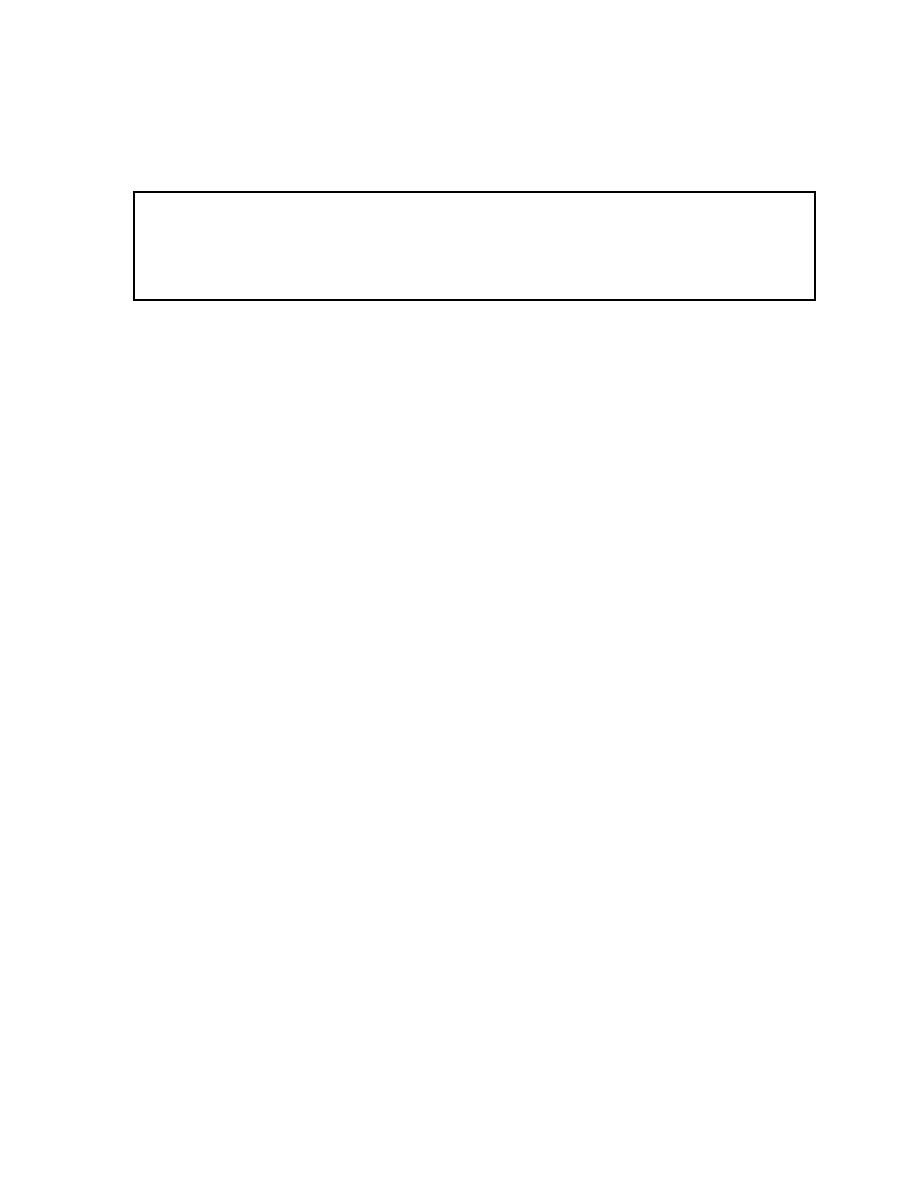

Table 1-5. Total dissolved solids categories

Category of Water

Total Dissolved Solids

Freshwater

0 to 1,500 PPM

Brackishwater

1,500 to 15,000 PPM

Saltwater

15,000 PPM or greater

A disadvantage is the possibility of high hydrogen sulfate in the raw water, causing fouling problems with

the RO membranes and taste and odor problems in drinking water. The RO membranes will not remove

gaseous hydrogen sulfide and will increase the corrosion of the bronze components of the ROWPU. When

chlorine is added to product water containing this gas, the hydrogen sulfide will convert to a solid and cause

the product water to cloud.

Removal of Hydrogen Sulfide. The presence of hydrogen sulfide alters taste and appearance but

does not affect the potability of the water. To remove hydrogen sulfide gas, personnel are to pump raw water

into a storage tank and aerate. This causes the sulfide to change to a solid and subsequently be removed by

the multimedia filter. Citric acid may also be injected into the raw water storage tank to decrease the pH to 4

or 5 PPM.

Placement of Offshore Intakes. The offshore intakes are the most popular type of saltwater intake.

They are sometimes required due to lack of time, personnel, or equipment required to develop beach wells.

In addition, coral formations sometimes prevent construction of wells. You can either use intakes of the rigid

pipe or float type. If possible, position either type in deep water beyond the surf action, and place intakes in a

vertical position. They must also be off the bottom and beneath the water surface at low tide. In this way, the

intakes will keep out foreign matter which may cause wear on purification equipment. Place the intakes of

rigid pipes on supports that are anchored securely in position by pilings. Floats securely anchored can

support intake screens the same as they do in inland surface waters.

Other Types of Wells. Wells are classified into five different types according to their method of

construction:

Dug. A dug well is one in which the excavation is made by the use of picks, shovels, spades, or digging

equipment, such as sand buckets or clamshell buckets.

Bored. A bored well is one in which the excavation is made by the use of hand or power augers.

Driven. A driven well is constructed by driving a pointed screen, referred to as a drive point, into the

ground. Casings or lengths of pipe are attached to the drive point as it is being driven into the ground.

Jetted. A jetted well is one in which the excavation is made by use of a high velocity jet of water.

However, in some regions of the Arctic, steam is used for jetting instead of water.

Drilled. A drilled well is one in which the excavation is made by either percussion or rotary drills. The

excavated material is brought to the surface by means of a boiler, sand pump, suction bucket, hollow drill

tool, or hydraulic pressure.

PART F INSPECTING WATER PRODUCTION OPERATIONS

Inspection. You should inspect each water point as needed using DA Form 5456-R (Water Point

Inspection) (Figures 1-7 and 1-8). Some water points require more attention than others, because of site

conditions or lack of experience of personnel operating the equipment. Once the historical data are

established, you may require more or less inspections of a water point. After completing inspections, forward

the results to higher headquarters.

1-16

QM 4923

Previous Page

Previous Page