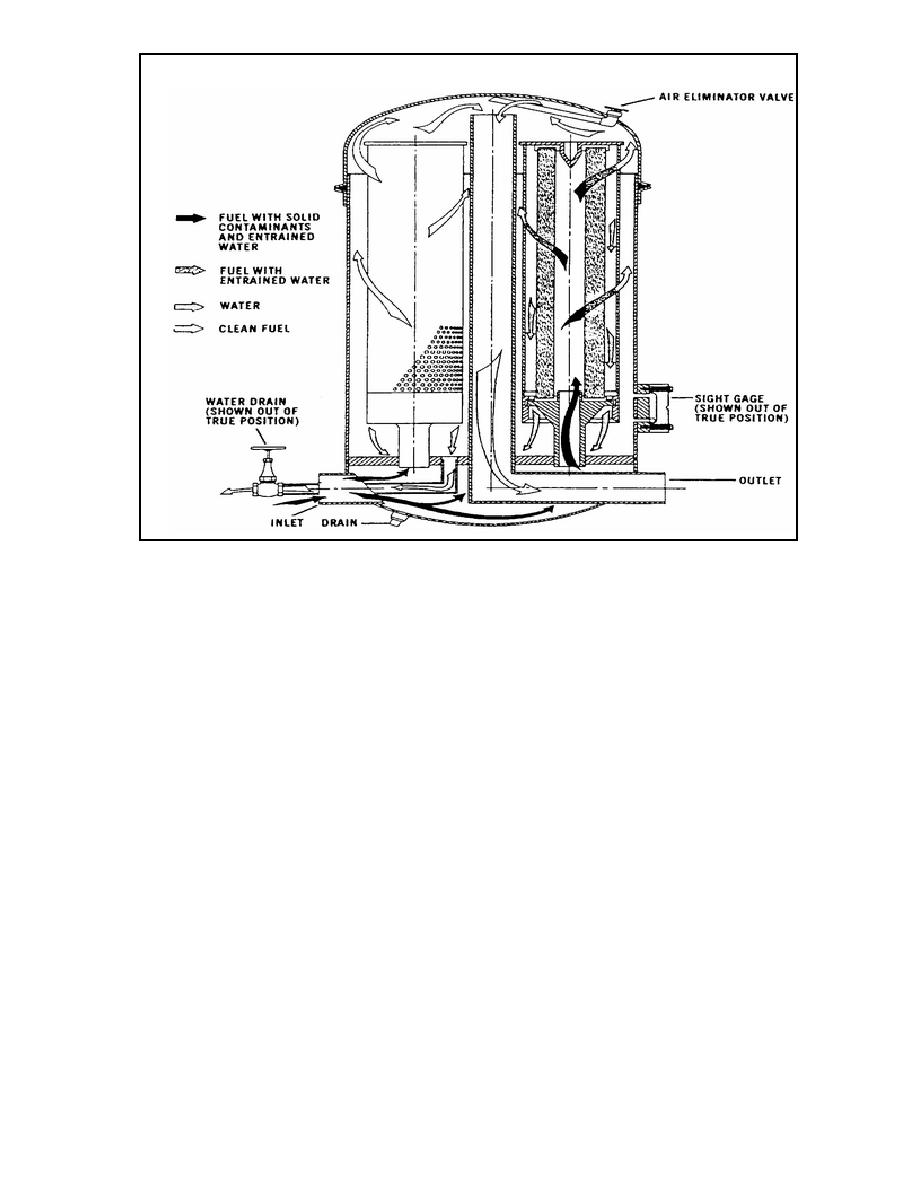

Figure 2-1. Typical flow through a filter/separator.

Performing After Operational Maintenance.

Clean and store the equipment.

Ensure all dust caps and plugs are installed after the operation.

Different Sizes of Filter Separators.

15 GPM liquid fuel filter separator is a vertical, portable unit consisting of an aluminum tank mounted on

an aluminum skid. This tank has fuel inlet and outlet valves, a water drain valve, and a water level sight

gage. The pressure vent valve's working pressure is 25 psi. The 15 GPM filter separator is used with

the 15 GPM hand operated dispensing pump.

50 GPM filter separator consists of an aluminum tank with removable cover, inlet pipe with dust plug,

outlet pipe with dust cap, water drain valve, an air vent valve, a pressure differential indicator, eight

glass, four elements and a canister. A reading in the green (0-20 psi) means the elements are clean. A

reading in the yellow (20-35 psi) means the elements must be changed at the end of the day's

operations. A reading in the red (35 psi and up) means the elements must be changed at once. The

maximum working pressure is 75 psi. It is used in refueling systems and for servicing ground vehicles.

100 GPM filter separator, aluminum pressure tank with removable head. The tank is welded in a tubular

aluminum frame. The maximum working pressure is 75 psi.

The 350 GPM filter separator is used in the 150 psi airfield refueling systems, motor fuel servicing

equipment and military hoseline systems, and as a component of the FSSP.

2-3

QM 5094

Previous Page

Previous Page