PART C - WATERFRONT FACILITIES

Multileg mooring systems.

Single-point mooring systems (mono buoy).

Jetties: Jetties are used when the water depth or the shoreline is unsuitable for bringing in tankers.

Docks and piers: Docks or piers (Figure 5-1) are the most secure for unloading tankers. Security is

easier to maintain. Access to the tanker is easier in case of emergency and for maintenance. They are

protected from winds and tide and should be separated from other classes of supply. The depth should

be at least 10 feet of water under the biggest tanker you expect to receive fully loaded at mean low tide.

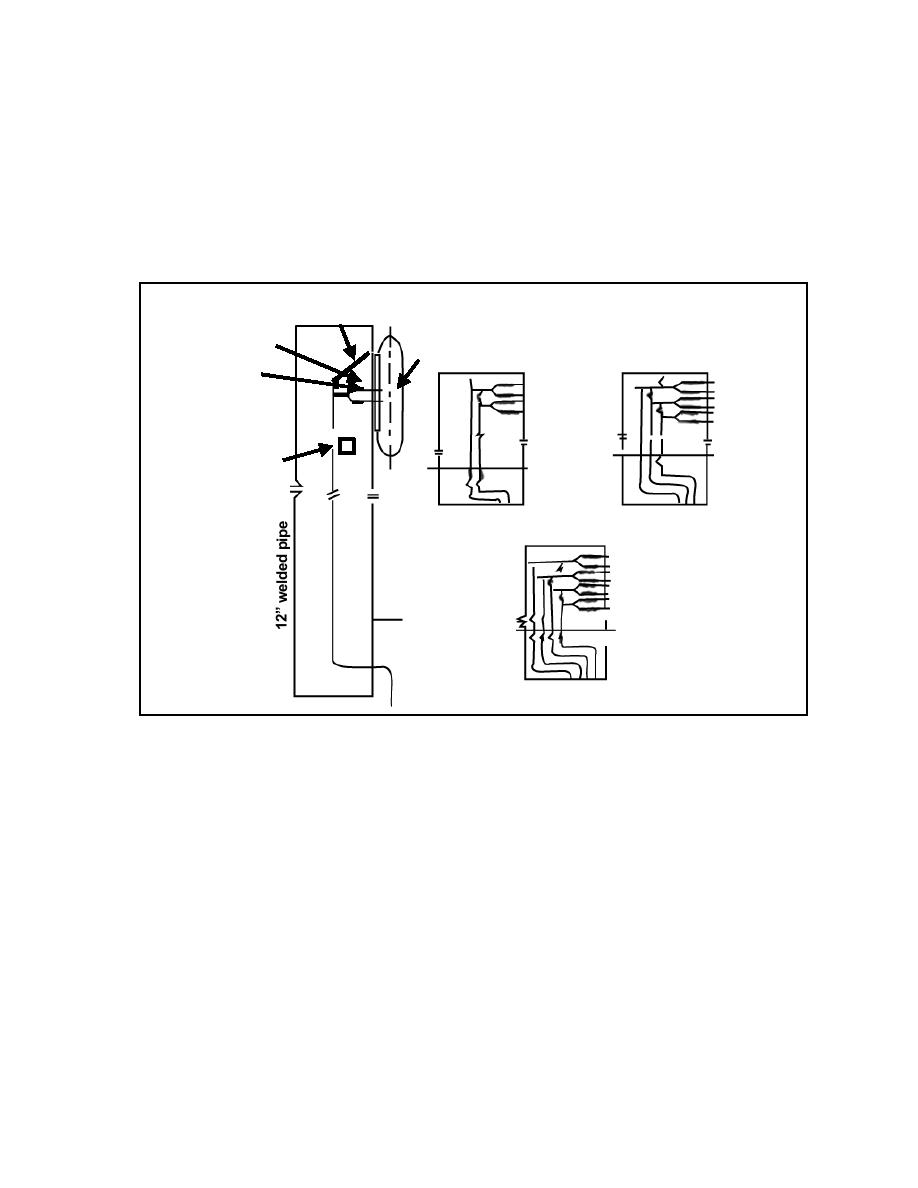

Unloading

Cable and Switch

8" Gasoline

Tanker

Hoses to Shoreline

Crotch

Dock

Dock

Shoreline

Spools

Shoreline

Dock

Two Facilities

Three Facilities

Dock

Tanker Unloading

Shoreline

Facility

Four Facilities

Figure 5-1. Layout of marine dock facilities for tanker unloading.

PART D - EQUIPMENT REQUIREMENTS

Storage tanks. Minimum of two tanks for each product and ballast water.

Oily water separator for treatment of ballast water.

Fire fighting equipment. Portable fire extinguishers and an engineer fire Figurehting detachment.

Pollution control equipment. Skimmer boats, absorbent materials, and containment booms.

Communications. Communications has to be from the dock to the ship and to the tank farm.

Transportation. Ground transportation and work boats for transporting men and equipment to the tanker.

Grounding system. For bonding the ship to the dock. If the dock has a cathodic protection system it

should be turned off before the transfer of fuel begins.

Base laboratory. A lab should be available for testing the products.

PART E - PREPARATION FOR ARRIVAL

The tanker arrival schedule is checked to ensure the type and quantity of product is known. Personnel are

required to meet the tanker and go aboard in the harbor. A terminal representative, lab technician, and

customs official may also be required. Make sure the berthing facilities are cleared for the tanker to tie up.

5-3

QM 5098

Previous Page

Previous Page