PART A - SUPERVISING THE OPERATION OF THE FSSP

Flow Through the FSSP. Inspect the fuel when it arrives. The product then enters the system through

the receiving manifold. It usually moves under suction from one of the 350-GPM pumps used as a receiving

pump. The product may also move under positive pressure from a transporter, pipeline, or hoseline. When

you have both filter/separators installed on the delivery side of the system, the receiving pump distributes the

product directly to the tanks through the hoseline manifold. The other 350-GPM pump is used to draw fuel

from the tanks and discharge it through the two filter/separators into the hose header system. When you

leave one filter/separator installed on the receiving side of the system, the receiving pump distributes the

product to the receiving filter/separator and then to the collapsible tanks. After that, the flow of product is the

same, except the fuel is drawn through only one filter/separator on the discharge side of the system instead

of two. You can also draw from the supply source directly to the discharge side of the system. This

procedure bypasses the storage tanks. You need only one pump and one filter/separator for this operation.

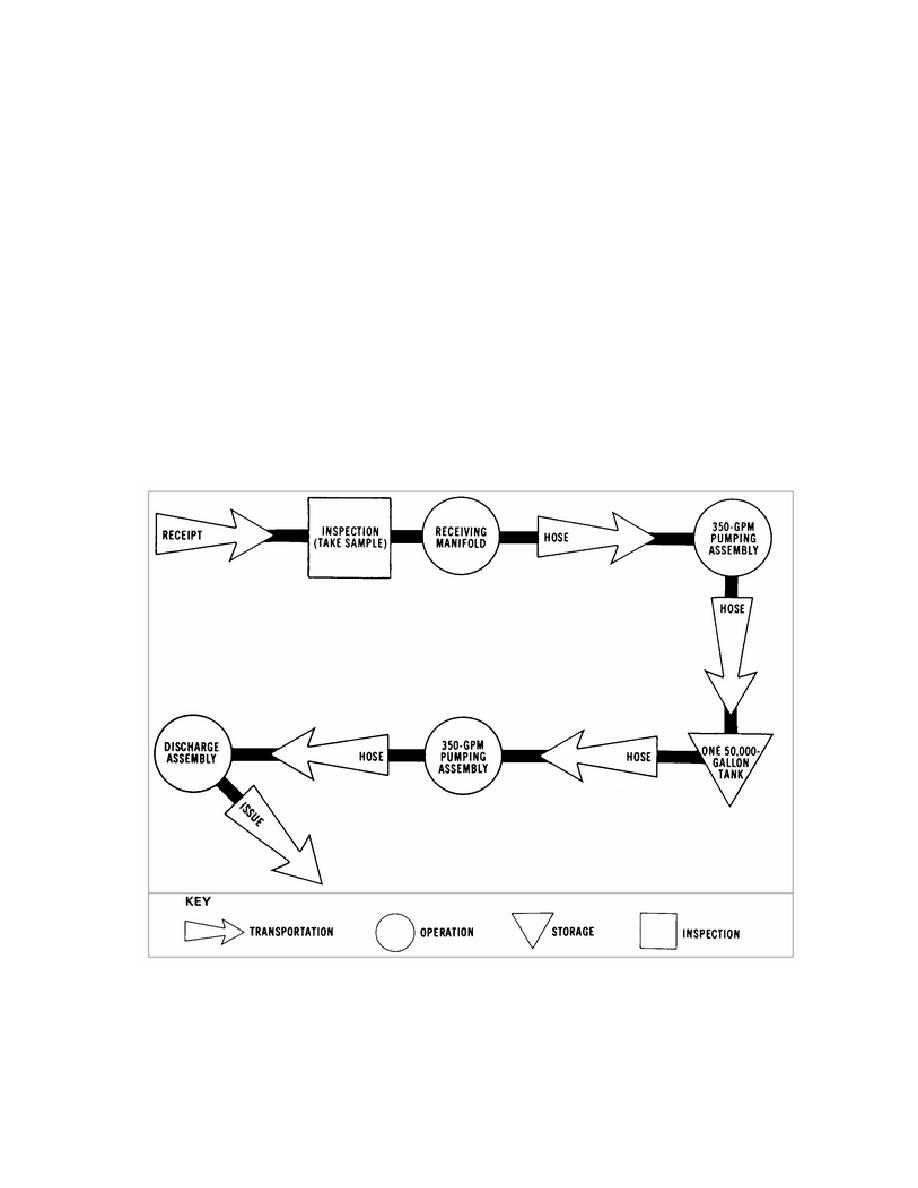

Flow Through the 50,000-Gallon Collapsible Tank. The first step is the inspection of the

product. The fuel then enters from the transporter through a receiving manifold made up of a suction hose

and gate valve. The product usually moves under suction from a 350-GPM pumping assembly that

distributes it into the 50,000-gallon collapsible tank. Another 350-GPM pumping assembly acts as a

discharge pump and distributes the fuel from the tank to the discharge hose assembly. The discharge hose

assembly consists of a gate valve and discharge hose. From the discharge hose assembly, the product

moves into a transporter (Figure 3-1).

Figure 3-1. Flow process chart for a 50,000-gallon collapsible tank.

Personnel. How you use your personnel is one of the most important parts of managing a Class III supply

point. In other words, how many do you need for a specific operation? Where should you place them in

relation to the equipment? What tasks should you give them to do? It is important that you assign specific

tasks to your personnel at the Class III supply point, but you should also try to be flexible. The best way to

3-2

QM 5095

Previous Page

Previous Page