Figure 3-8. Loading from the dome.

Follow-Up Procedures. After loading the car, follow-up procedures are performed. Allow product to

stand for 15 minutes so that suspended water or sediment can settle. Gage and sample contents of tank.

Take temperature of product, correct volume to 60 degrees Fahrenheit, and record data. Retain sample for

reference until car has been delivered. If tank contains any water or sediment, drain it from the tank, and

again load product until the tank is full. After daily closing gages are taken, compare total storage tank issue

with total quantities loaded on tank cars. Report excessive loss to proper authority. When tank car is full of

product, replace bottom outlet and cap, and close and lock dome cover. Place an identification seal on the

dome cover; it must be an approved seal, one which cannot be removed without being destroyed. The

receiver is assured that the car has not been tampered with if the seal is in place. Record the seal marking

on all shipping papers. Remove the drainage tub from under the bottom outlet, and discard any product that

is in the tub. If the car has DANGEROUS-EMPTY placards, remove them and replace them with

FLAMMABLE placards. Some placards bear the two signs; they only need to be reversed. Disconnect

grounding wire from tank car; remove derails, if provided; and remove TANK CAR CONNECTED signs.

Release brakes and remove car from transfer area.

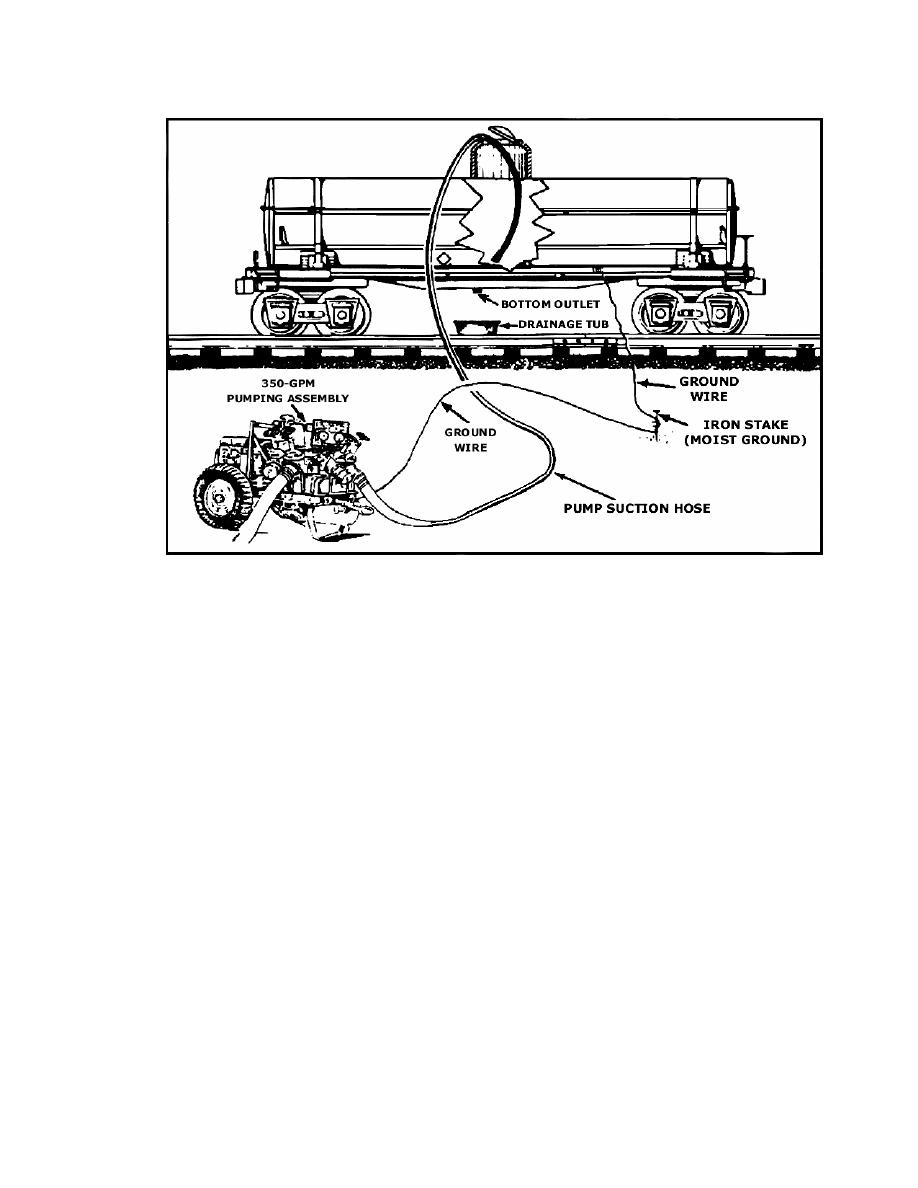

PART M - PROCEDURES FOR UNLOADING TANK CARS

Equipment preparation. Inspect the unloading equipment such as pumps, hose, loading racks, pipelines,

and manifolds to see that they are clean, free of any contaminating product, and in good operating condition.

When possible, use equipment exclusively for handling one product. If it is necessary to use the same

equipment for handling several products, drain the equipment thoroughly of preceding product before

introducing the new product into the line. If product in tank car is to be transferred to cans, drums, tank

trucks, or semitrailers, inspect the containers or vehicle and make sure that they are clean and in good

condition. If the product in the tank car is to be transferred to storage tanks, make sure that the tanks are

clean and suitable for receiving the assigned product. If the tanks are not clean, they must be freed of

vapors and cleaned before receiving product.

3-14

QM 5098

Previous Page

Previous Page