the outlet valve and allow product to drain into tub. Close the outlet valve, but do not replace the outlet cap

until the car is completely loaded. Dispose of any product collected in the drainage tub, and place tub in

position to catch additional leakage.

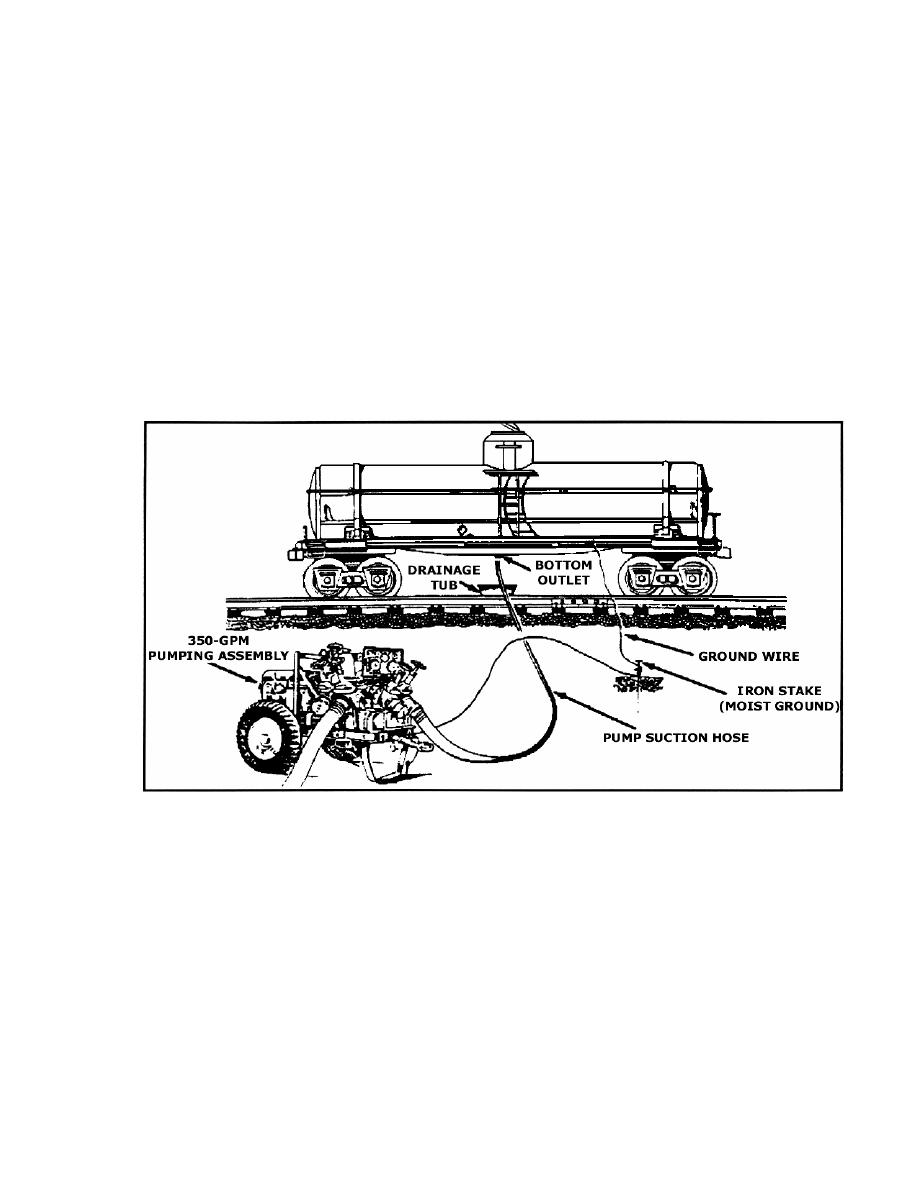

Loading Product. Tank cars should be loaded through the bottom outlet (Figure 3-7) whenever possible

to prevent vapor loss, reduce the generation of static electricity, and protect the fuel against contamination

from outside sources. To bottom load a tank car, proceed as follows: Locate and ground a pumping

assembly at least 50 feet away from the tank car. Make sure that the supply container is properly grounded

and vented. Connect the hose lines, taking care to prevent hose connections from lying on the ground or

from becoming otherwise contaminated. Station a man on the windward side of the dome to signal when the

full mark is reached. Before starting the pump, open the appropriate valves to avoid pumping against a

closed system. Start the pump and observe safety precautions. When the transfer operation is halted for

any reason, disconnect the pump discharge hose. When the level of product in the tank car is near the full

mark or bench mark, signal the pump operator to reduce the pump speed and be alert to stop the pump.

When using a loading rack or other system that provides a control valve, reduce the flow of product into the

tank by partially closing the valve. If the tank does not have a full mark, load the tank until the product

reaches the top of the shell. When the product reaches the full mark or top of shell, shut down the pump,

close all valves, and disconnect the pump discharge hose.

Figure 3-7. Loading from the bottom.

Top loading. Top loading is done only in emergency situations when bottom loading is not possible and

is accomplished by inserting the end of the loading hose or drop tube through the dome of the tank until it

almost touches the bottom of the tank (Figure 3-8). If the hose or drop tube does not extend far enough into

the tank, the product splashes, causes undue loss of product through vaporization, and creates a potential

fire hazard. Make sure that there is no unnecessary strain on the hose, which could cause the hose to move

or come out of the tank during the transfer. Before starting the pump, open the appropriate valves to avoid

pumping against a closed system. When all connections are secure and the necessary valves are open,

start the pump. When product starts to flow into the tank, observe the bottom outlet to see if there is any

leakage. If leakage is apparent, stop the pump and attempt to seat the bottom outlet valve by turning the

valve rod handle in a clockwise direction. If the leak cannot be stopped, discontinue loading operations,

recover product from the tank, and clear the area of spilled product. Follow safety precautions as given for

bottom loading above.

3-13

QM 5098

Previous Page

Previous Page