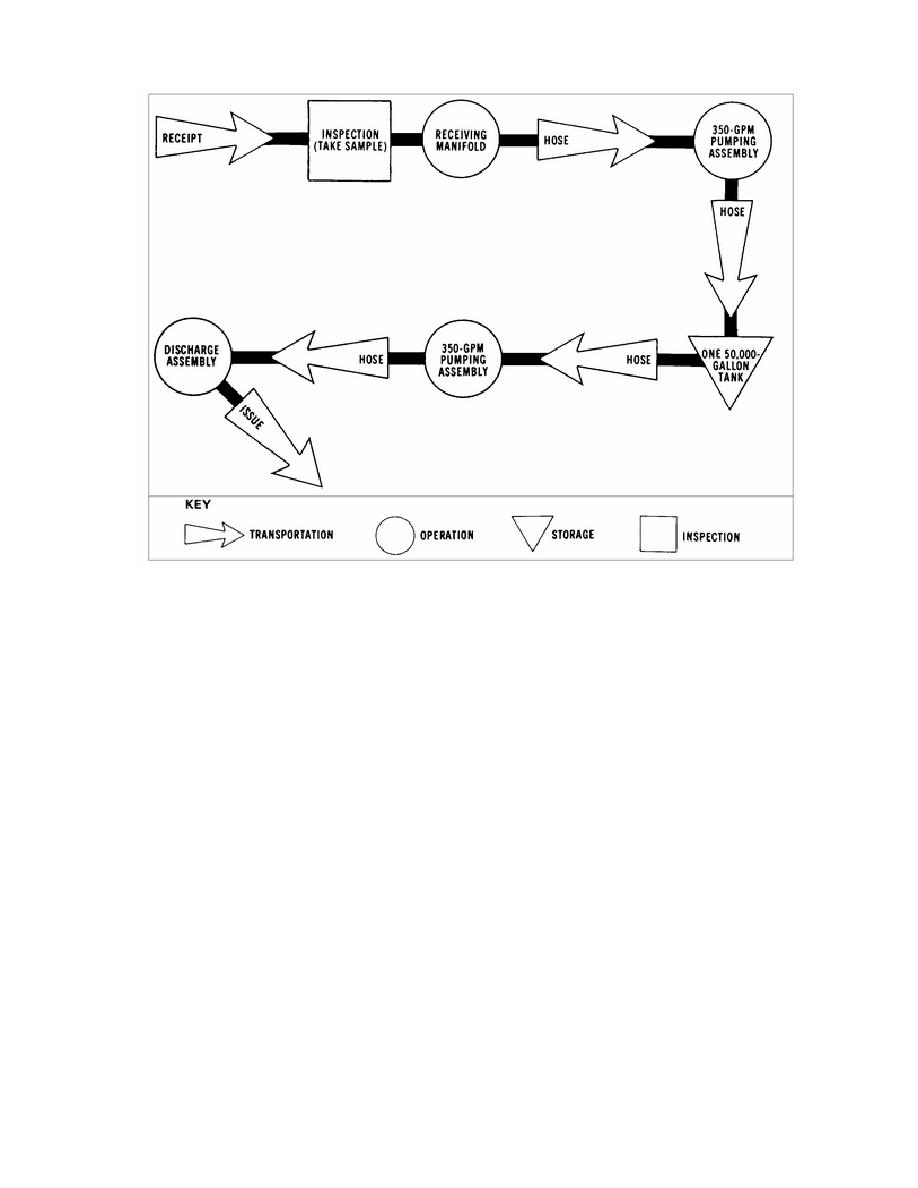

Figure 5-1. Flow process chart for a 50,000-gallon collapsible tank.

Personnel. How you use your personnel is one of the most important parts

of managing a Class III supply point. In other words, how many do you

need for a specific operation? Where should you place them in relation

to the equipment? What tasks should you give them to do? It is

important that you assign specific tasks to your personnel at the Class

III supply point, but you should also try to be flexible. The best way

to use all of your personnel wisely is to let the job determine the

assignment. For example, if you have no issues scheduled for the FSSP,

you can use the workers assigned there to improve the fire walls around

the collapsible tanks. On the other hand, there may be a time when the

supply point, or a section of it, is not busy. You may then use your

workers to improve the camouflage and concealment of the area, improve

drainage ditches and roadways, make sure the safety equipment is

serviceable, and do operator and organizations maintenance on the

equipment in the supply point. Although the number of persons you assign

to a specific task may vary greatly with your mission, it is still

possible to obtain an average number for each operation.

For a single shift, you need eight workers to operate the FSSP

efficiently. Place them at certain strategic points in the operation.

Assign two workers to the receiving manifold. They operate all valves at

the receiving point and make all necessary hose connections. Assign

three workers to the pumps and control valves. Have one worker operate

each pump, and the third worker operate the discharge and receiving

manifold of the collapsible tanks. Assign three workers to the delivery

side of the system. Make them responsible for dispensing petroleum and

12-52

QM 5099

Previous Page

Previous Page