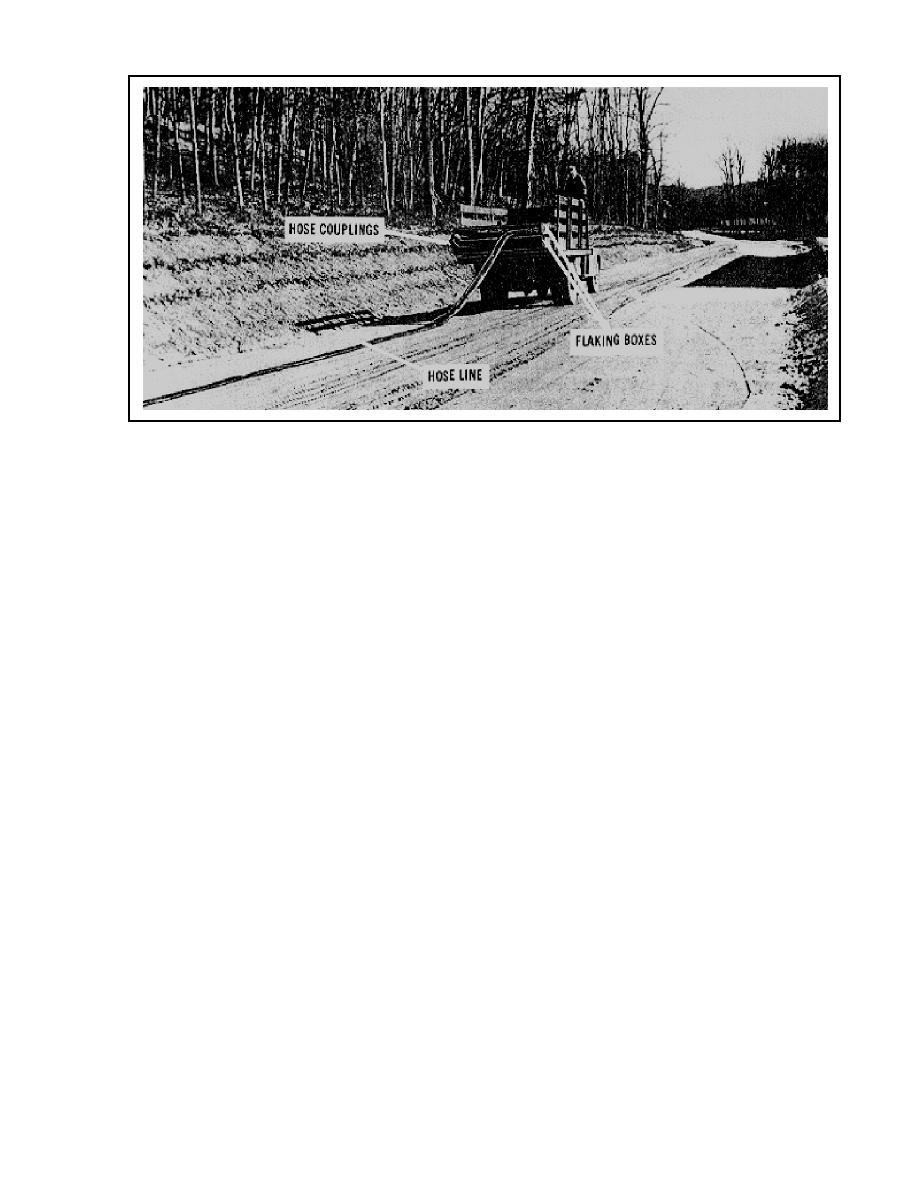

Figure 6-1. Laying the assault hoseline on a road.

Crossing Streams. There are several ways you can ensure that personnel lay the hoseline across a

stream or water course. If there is a bridge, suspend the hoseline on improvised brackets outside the bridge

railing. If there is no bridge, personnel may lay the hoseline directly in the streambed if it is narrow and not

apt to flood. Use the hoseline suspension kit to cross a wide stream. Fabric saddles, with eyes for easy wire

attachment, come with the kit.

Crossing Gaps. Personnel should also use the hoseline suspension kit to span small gaps with steep

sides. For a wide crossing, ensure that personnel build a suspension bridge with a flat deck or floor to hold

the hose. This eliminates the sags that occur when the suspension kit is used.

Crossing Roads. To cross a highway or railroad, run the hoseline under a bridge or through a culvert, if

possible. Personnel can pull the hoseline through the culvert with a rope or push it through with a piece of

lumber or a small-diameter pipe. If there is no bridge, ensure that personnel install the roadway crossing

guard to protect the hoseline. Never bury unprotected hoseline in a railbed. When crossing a railbed,

personnel can either install a piece of heavy wall pipe in a shallow ditch under the rails or suspend the hose

over the railbed at a suitable height. As soon as possible, replace the hoseline at a railway crossing with

welded pipeline because of the fire hazards caused by trains.

Pumping Stations. Assault hoseline pumping stations have one 350-GPM pumping assembly. If you

are using only one hoseline outfit, ensure that personnel place the pumping assembly at the beginning of the

hoseline system. Because this pump does not have a pressure-regulating device, you must monitor it at all

times for changes in hoseline pressure. Personnel must set up pumping stations when they connect hoseline

outfits together. There is a formula you can use to locate pumping stations on level ground using motor

gasoline in the hoseline. If you use a product other than motor gasoline, the distance between pumping

stations (given by this formula) changes. For example, if you use a product heavier than motor gasoline, the

pumping stations should be closer together. If the product you use is lighter than motor gasoline, the

pumping stations should be further apart. The distance between pumping stations (given by this formula) also

changes with the height of the terrain. For example, if you place the hoseline on an uphill slope, the pumping

stations should be closer together. If you place the hoseline on a downhill slope, the pumping stations should

be farther apart.

Hoseline Testing. Once personnel have set up the assault hoseline, they should fill it, pressurize it, and

check the hoseline for leaks. Ensure that personnel start the pumps slowly and raise the fluid pressure in the

system gradually in increments of 50 PSI. Ensure that personnel hold the pressure each time they raise it,

and inspect the hoseline for leaks. Keep doing this up to and including 150 PSI. Even though the design

12-60

QM 5099

Previous Page

Previous Page