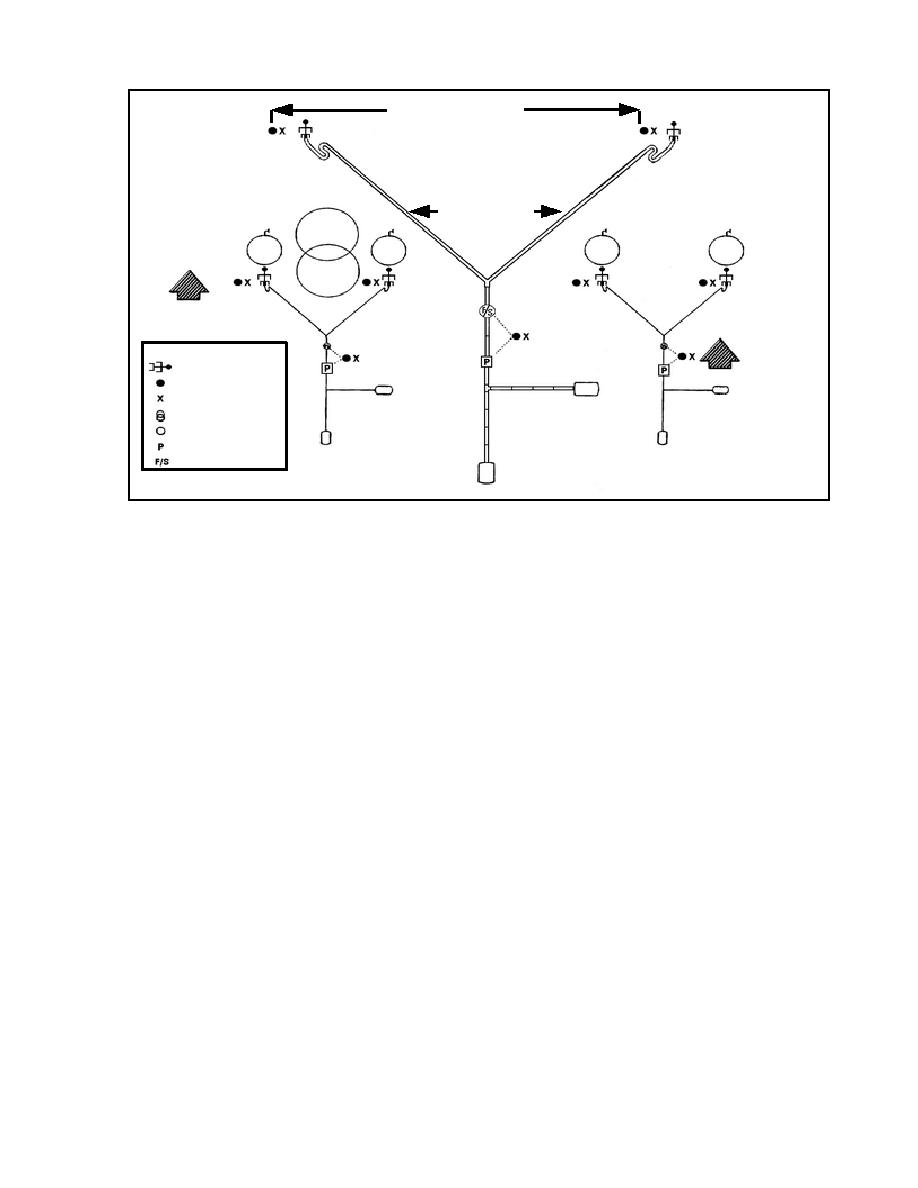

Approximately 100 Feet

Discharge Hose

Wind

LEGEND

CCR Nozzle

Wind

Ground Rod

Fire Extinguisher

Refueling OH-6, OH-58,

CH-47

AH-1, UH-60A, AH-64, and

Single Rotor Aircraft

UH-1 Single Rotor Aircraft

Pump

Refueling CH-47

Filter/Separator

or CH-54 Aircraft

Figure 7-1. Typical FARE layout.

PART C - QUALITY SURVEILLANCE

The quality and cleanliness of turbine fuel are vital to the safety of turbine-engine-powered aircraft. Turbine

engines have more stringent cleanliness requirements than do reciprocating engines. Because turbine

engines have high fuel consumption rates, contaminants accumulate in them rapidly. Turbine engine filters

cannot remove fine sediment, excess amounts of sediment, or water from the fuel. Separating the

contaminants from JP-5 and JP-8 is time-consuming and further complicated by their high viscosity and

specific gravity. Any unit or organization that has military-owned aviation fuel in its physical possession is

responsible for establishing and maintaining an adequate quality surveillance program. Each person involved

in aircraft refueling is responsible for ensuring that the fuel pumped into an aircraft is clean, bright, on

specification, and does not contain any free water or sediment.

Quality surveillance testing and sampling are used to find common contamination hazards. The hazards

that may affect aircraft are sediment, water, microbiological growth, and commingled fuel. Since each aircraft

engine is designed to burn one particular type and grade of fuel, the consequences of using a mixture of

different fuels can range from small variations in engine performance to total loss of power and engine failure.

The consequences of commingling depend on the physical properties of the fuel.

Sampling and Testing. How often aviation fuels are sampled and tested depends on several factors. It

depends upon whether the fuel is taken from a fuel source, a system or refueler, or an aircraft tank. Fuel

supplies must be tested to confirm their identities (API gravity test) and detect water (Aqua-Glo test) and

particulate contaminant by color comparator ratings. Samples of fuel to be dispensed to aircraft should

contain no more than 10 fibers when a 1-quart sample is visually examined. The aviation fuel contamination

test kit is designed to provide a final check on aviation fuel just before the fueling of an aircraft. It includes the

API gravity test, the Aqua-Glo test, and the Millipore test (a test for particulate contaminants). Fuel in aircraft

tanks must be checked by the aircraft crew before flight operations begin. Taking a preflight sample is the

only way of ensuring that the fuel on board does not contain water or other visible contaminants. Any fuel that

fails a visual check should be segregated and held until laboratory test results are received. To check a fuel,

choose a clean sample bottle, draw a fresh sample, visually inspect it, and test it for debris, foreign matter, or

water. Laboratory testing ensures that the fuel's quality meets specifications, unknown products and existing

12-66

QM 5099

Previous Page

Previous Page