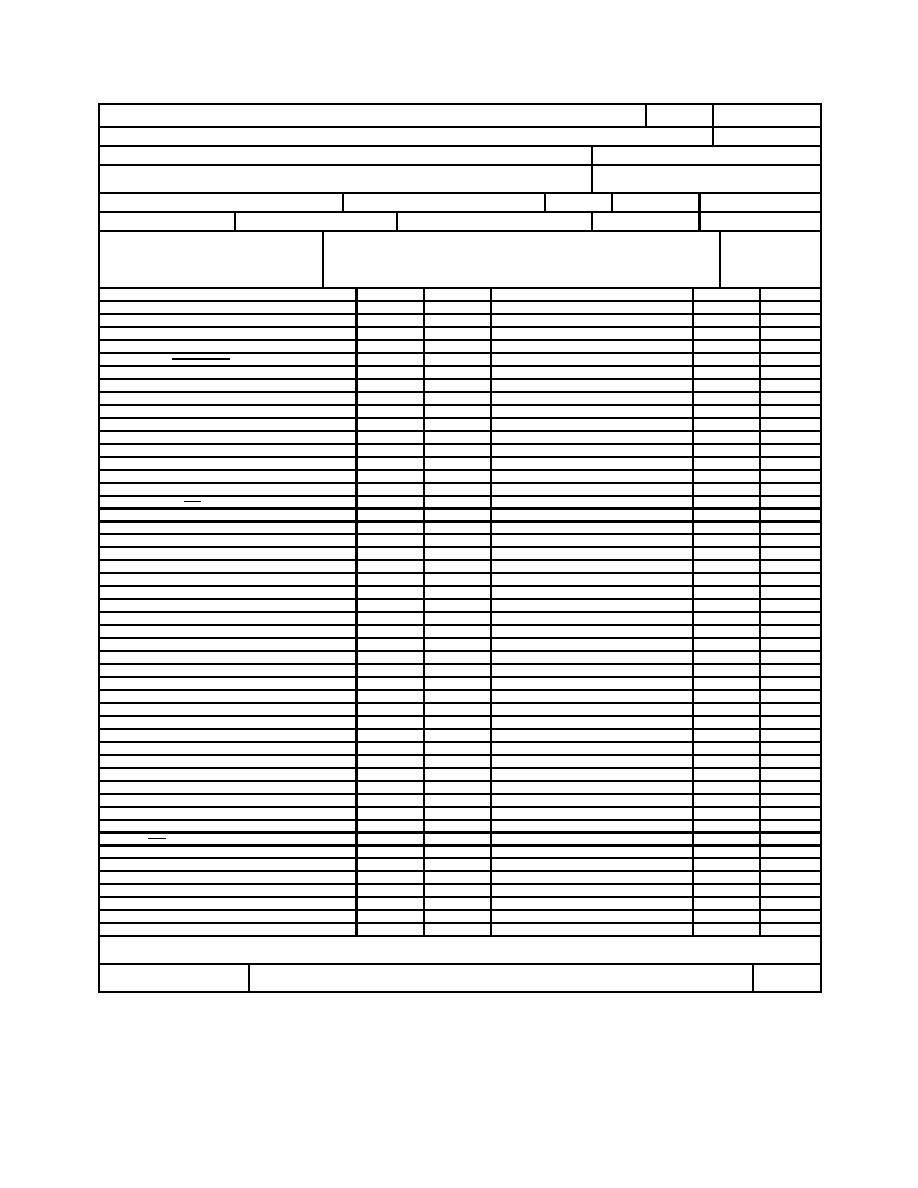

SAMPLE NO.

LAB REPORT NO.

PETROLEUM PRODUCTS LABORATORY ANALYSIS REPORT

XX - 017

XX - 1717

For use of this form, see FM 10-67-2; The proponent agency is TRADOC

PRODUCT NOMENCLATURE AND TYPE

SPEC. NO.

FUEL OIL, DIESEL, MARINE DFM

MIL-F-16884

SAMPLE SUBMITTED BY (Installation)

AMT PROD SAMPLE REPRESENTS

POHANG TERMINAL, KOREA

10 M BBLS

MANUFACTURER OR SUPPLIER OF PRODUCT

SOURCE OF SAMPLE (Truck, Tank, Aircraft, etc.)

PDSK-Trans Korean Pipeline Korea (CONUS)

Tank 25 (Multi Prod Line Used)

SAMPLE TAKEN BY (Name)

CONTRACT NO.

ITEM NO.

FSN

DATE SAMPLE TAKEN

BP5 JENNINGS

914-00-273-2377

Today

QUAL NO.

BATCH NO.

FILL DATE

DLVR DATE

DATE SAMPLE REC

YESTERDAY

Today

NAME AND LOCATION OF LABORATORY

x FUEL BULK STORAGE

DATE TESTS STARTED

ROUTINE SURVEILLANCE

Pohang Laboratory

Today

FUEL PACKAGED

PROCUREMENT ORIGIN

Camp Libby, Korea

ALLIED PRODUCTS

PROCUREMENT

DATE TESTS COMPL

FILTER EFFECTIVENESS

SPECIAL

Today

QUALIFICATION CONTRACT

DEPOT

TEST

SPEC/QUAL

RESULT

TEST

SPEC/QUAL

RESULT

27. WATER AND SEDIMENT % VOL

MAX

1. GRAVITY API/SP GR 60/60F

TOP

a.

MID

28. FSII % VOL

TOP

b.

BOT

a.

MID

c.

AVG

RPT

35.0

b.

BOT

2. APPEARANCE/WORKMANSHIP

C& B

Opaque

c.

AVG

3. COLOR

VISUAL

29. PARTICULATE CONTAMINANT MGS/GAL

a. HELLIGE (Colorimeter)

30. THERMAL STABILITY INCHES HG

b. ASTM MAX/SAYB MIN

3

4

a.

PREHEATER RATING

c. SAYB AFTER HEAT MIN

31. SULFIDES (Tank Water BTMS)

4. ODOR

32. WATER SEPAROMETER INDEX MIN

5. DISTILLATION

1BP

C

RPT

171.0

33. % ASH PLAIN/SULF MAX

a.

5

% REC -

EVAP AT

C

RPT

300.0

34. % LEAD

b.

9

% REC -

EVAP AT

C

357

360.0

35. % PHOSPHORUS

c.

% REC -

EVAP AT

C

36. % CHLORINE

d.

% REC -

EVAP AT

C

37. BURNING TEST (16 hrs)

e.

FBP/DRY PT

MAX C

385

388.0

38. KIN CS/SSU AT

,F

f.

% RECOVERED

RPT

96.0

a. KIN CS/SSU AT

,F

g.

% LOSS

b. KIN CS/SSU AT

,F

h.

% RESIDUE + Loss

MAX

3.0

4.0

c. KIN CS/SSU AT

,F

i. 10% + 50% EVAP

,F MIN

d.

SSF AT

,F

6. ENGINE RATING O.N. MOTOR METHOD

e. VISCOSITY INDEX MIN

a. ON RESEARCH METHOD

39. EVAP LOSS % MAX

b. LMR AVIATION METHOD

40. PRECIPITATION NO MAX

c. RMR SUPER CH METHOD

41. SEPARATION % MAX

d. CETANE NUMBER/INDEX MIN

42. ACID NO/BASE NO MAX

7. RVP (PSI)

43. CHANNEL PT

,F MAX

8. GUM EXISTENT MG/100 ML MAX

44. SAPONIFICATION NO MAX

GUM (Wash)

MG/100 ML MAX

45. DIELECTRIC STRENGTH KV MIN

GUM POTENTIAL MG/100 ML MAX

46. FOAM SEQ 1. MLS MAX (TND/STAB)

PRECIPITATE MG/100 ML MAX

a. SEQ 2. MLS MAX (TND/STAB)

9. TEL/TML (ML/GM/GAL) MAX

b. SEQ 3. MLS MAX (TND/STAB)

10. OXIDATION STABILITY MINUTES

47. PENETRATION UNWORKED

77,F

11. DR TEST/MERC S% MAX

a. PENETRATION WORKED

77,F

12. SULFUR BY LAMP BOMB % MAX

48. DROP PT/MELT PT

,F MIN

13. FREEZING PT

,F

49. CORR AND OXIDATION STAB

14. CORROSION COPPER STRIP

3 HR @ 122 degrees F

50. SWELLING SYN RUBBER %

15. AROMATICS % VOL MAX

51. LOW TEMP STABILITY

16. OLEFINS % VOL MAX

52. SALT SPRAY TEST

17. SMOKE POINT MM MIN

53. WORK STABILITY

18. SMOKE VOLAT INDEX MIN

54. WATER STABILITY

19. ANILINE PT

,F/ANILINE GRAV PROD MIN

55. THICKENER TYPE

20. FLASH/FIRE POINT

,C MIN

60

80

56. THICKENER CONTENT %

21. CLOUD POINT

,F MAX

57. CORROSION PROTECTION

22. POUR POINT

,F MAX

58. REMOVAL

23. WATER REACT INTERFACE RATING MAX

59. APPARENT VISC AT

,F

a.

VOLUME CHANGE MAX

a. SHEAR RATE POISES

24. CARBON RESIDUE % WT MAX

10% Bottom

.20

0.258

60. S ED CONTAM. MILLIPORE, MG/L, MAX

25. WATER % VOL MAX

61. EFFECTIVENESS OF FILTRATION

25. SEDIMENT % VOL MAX

62. OTHER (Specify)

REMARKS

SFU. Item # 5.h. within use limits. Recommend using ashore as boiler fuel or in low-speed stationary diesel engines.

DATE FORWARDED

SIGNATURE

TITLE

DA

2077

FORM

EDITION OF 1 MAR 62, IS OBSOLETE

HU.S. GPO: 1989-0-230-313

Figure 1-2, DA Form 2077 (Petroleum Products Laboratory Analysis Report).

1-5

QM 5184

Previous Page

Previous Page