(2) Fill the prover and then empty to the zero mark (dry run). This removes air pockets in the line

and warms up the meter.

(3) During the dry run, the time and flow rate can be determined.

(4) All gages and thermometers will be checked for accuracy.

(5) All fittings and valves must be checked for leaks.

d. Verification records and reports.

(1) Meter test results.

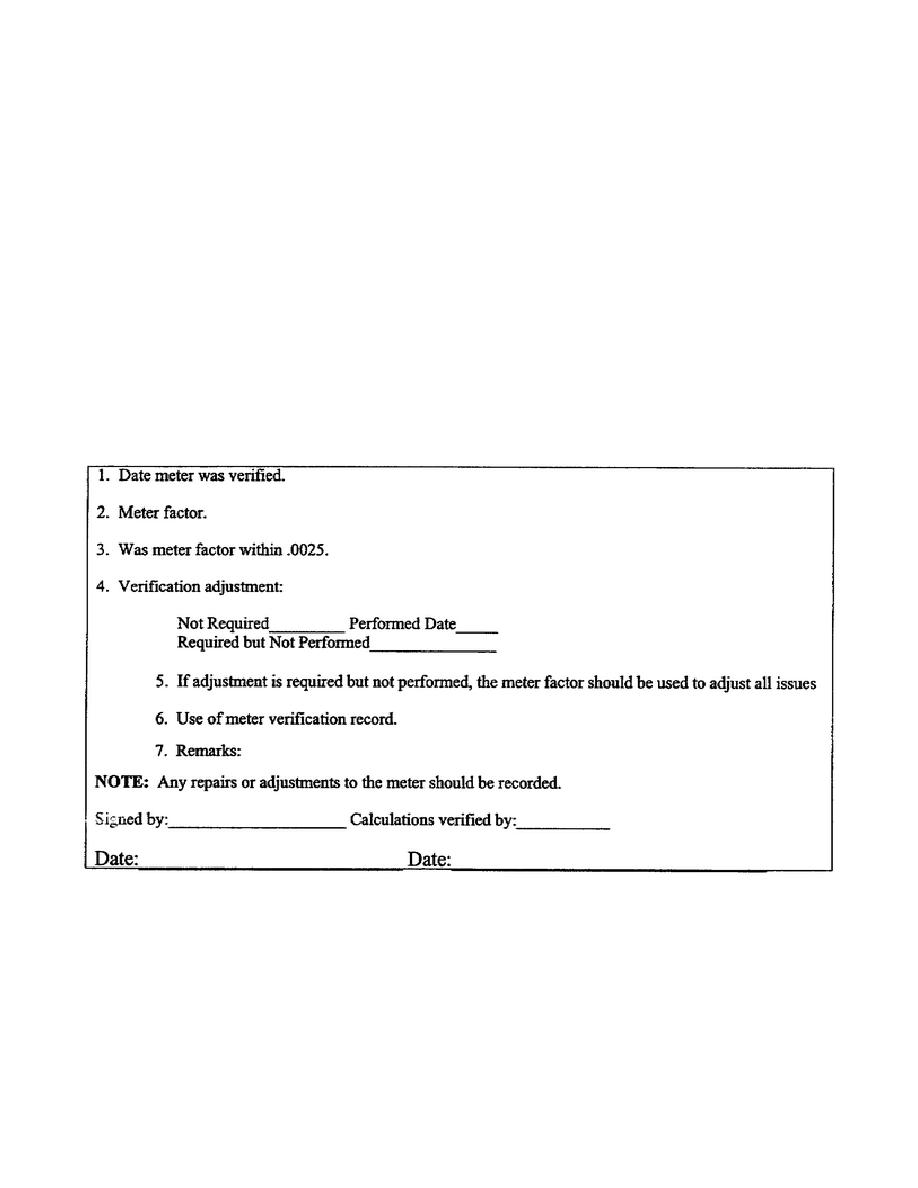

(2) Meter certification record. The meter certification record in conjunction with the meter test

results is your proof that the meter has been properly calibrated.

NOTE: This certification also includes open volumetric prover. If you are not using this type of prover include

only necessary information.

Figure 17-1. Sample meter certification record.

e. Conducting the meter verification.

(1) Return meter reading to zero.

(2) Fill prover can, stopping flow as close to the zero mark in the graduated neck as possible. Fuel

cut line must be in the graduated neck.

QM5200

17-6

Previous Page

Previous Page