INTRODUCTION

Since the days of World War II, petroleum NCOs have grappled with the challenges of moving fuel to the

front lines of battle quickly and efficiently. Today's NCOs now have an advantage over their predecessors

because they accomplish the task with the Army's inland petroleum distribution system (IPDS). The IPDS is

the Army's primary method of receiving, storing, and distributing bulk fuel to support military forces deployed

in worldwide contingency operations. The system consists of both commercial and military petroleum

equipment made up of three primary subsystems: the tactical petroleum terminal (TPT), pipeline

components, and pump stations. By successfully integrating these elements, troops can move fuel from any

source forward into the theater of operations.

PART A - COMPONENTS

Inland Petroleum Distribution System (IPDS) is designed as a lightweight, rapidly deployable pipeline and

terminal system that can be used in undeveloped and developed theaters of operation. It can interface with

an existing host nation fuel source, such as a refinery, or with the Navy's Offshore Petroleum Discharge

System (OPDS). The Navy is responsible for delivery of petroleum from offshore tankers to the high-water

mark. The system is modular in design and can be tailored for any locality or operation.

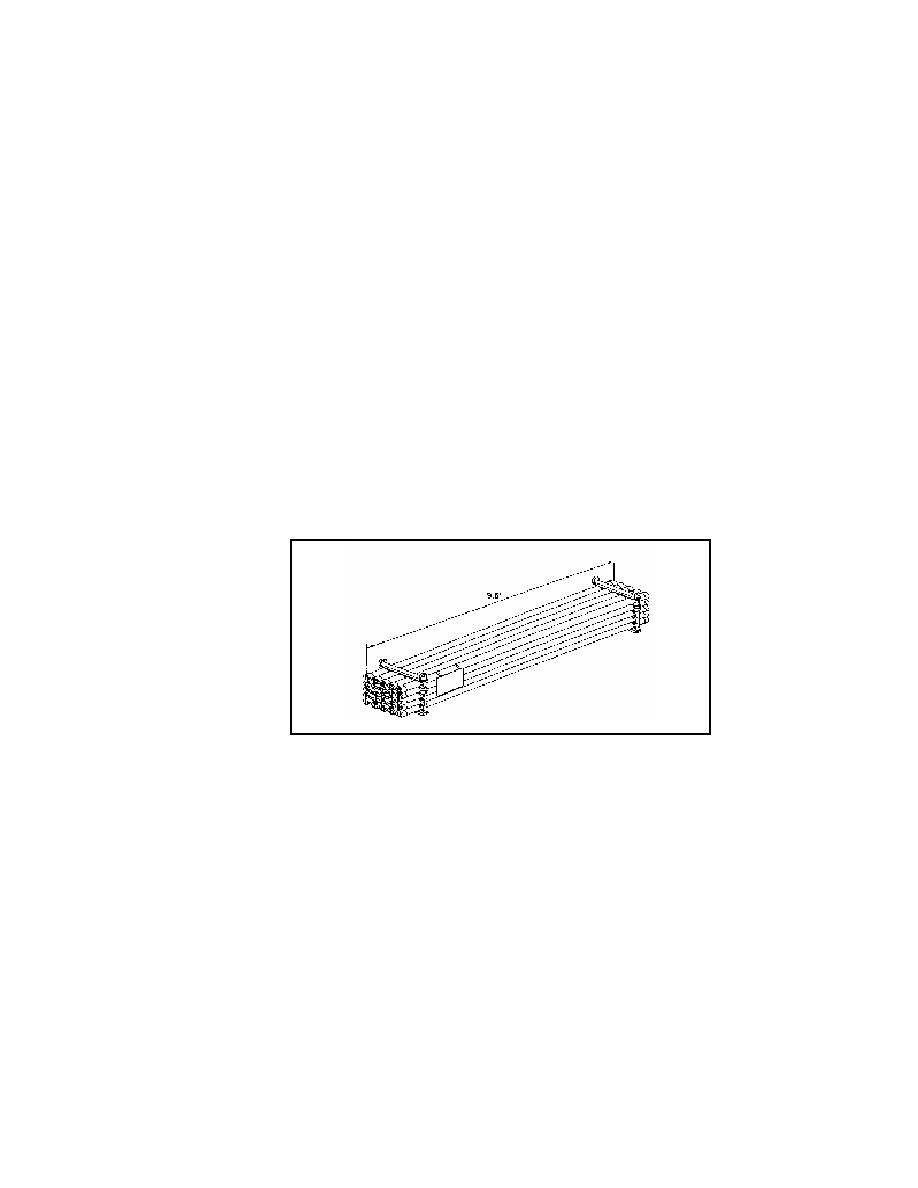

Pipeline. The pipeline is configured in 5-mile pipeline sets. There are 2,779, 9.5 foot pipe sections in

each 5-mile set and 10 sections with each pump station. As they are of a constant wall thickness (0.404``),

they can be cut to any length required and regrooved using the cutting and grooving tool furnished. They are

used to close short gaps in the pipeline. Each section has a black line down the length for easy identification

of nipple material.

Figure 2-1. 9.5-foot aluminum pipe sections.

Major Components.

5-Mile Pipeline Set:

Valves, Elbows, and Supplies, Container 1 of 13.

Coupling Clamps and Nipples, Container 2 of 13.

Coupling Clamps, Containers 3 and 4 of 13.

Pipe, Containers 5 through 13 of 13.

Pipe Connection Assembly:

Switching Manifold, Container 1 of 5.

Contaminated Fuel Module, Container 2 of 5.

Fire Suppression Equipment, Container 3 of 5.

Transfer Hoseline Assembly (Tricon), Container 4 of 5.

PLCA Support Assembly, Container 5 of 5.

Pipeline Support Equipment:

600-GPM Pump and Spare parts, Container 1 of 5.

Cutting and Grooving Machines, Container 2 of 5.

Pipe Nipples, 3 of 5.

2-2

QM 5096

Previous Page

Previous Page