Pioneer Tool Kits and Valves, Container 4 of 5.

Gap Crossing and Sandbags, Container 5 of 5.

Recovery Equipment:

Pumps and Tools, Container 1 of 3.

Safety Supplies and Forms, Container 2 of 3.

Cleaning Compounds and Paint, Container 3 of 3.

Suspension Bridge:

100-Foot Pipeline Suspension Bridge.

200-Foot Pipeline Suspension Bridge.

400-Foot Pipeline Suspension Bridge.

Base, Towers, and Anchors, Container 1 of 2.

Cable and Supplies, Container 2 of 2.

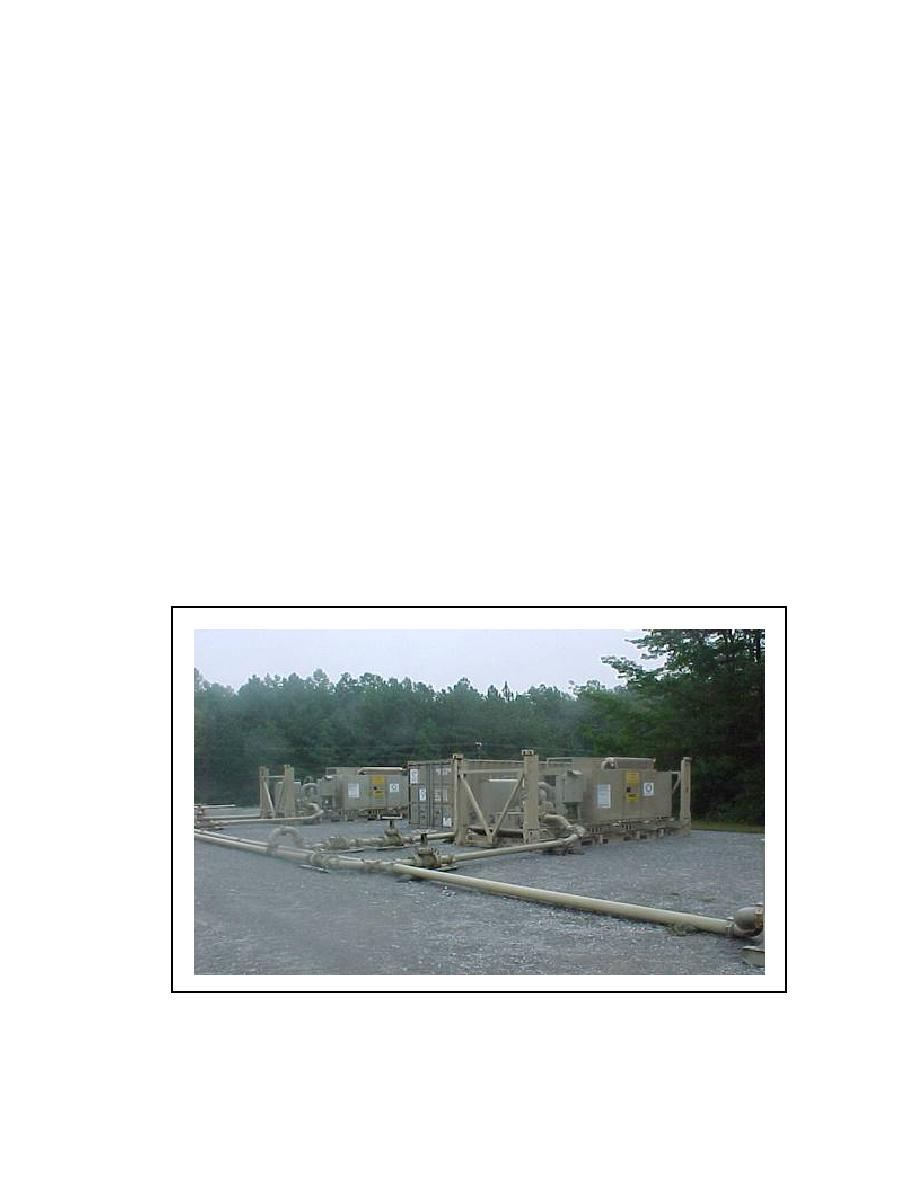

Pump Stations. Each pump station has two skid-mounted, diesel engine driven (three stage centrifugal)

mainline pumps, with an operational output of 800 GPM (Figure 2-2) at 1,800 feet of head, at 2,100 rpm.

Only one is operated at a time. Launcher and receiver assemblies (Figure 2-3), a dual in-line strainer

assembly (Figure 2-4) located on the incoming side of the station, and a floodlight set are also components

of pump stations. Except for the mainline pumps, all pump station equipment will be stored in four 20-foot

ISO containers. More detailed descriptions and illustrations of pump station equipment can be found in FM

10-67-1 (Concepts and Equipment of Petroleum Operations), Chapter 7.

Pipeline Pump Station:

Launcher and Receiver Assembly, Container 1 of 6.

Valves and Fittings, Container 2 of 6.

Floodlight Set and Spare Parts, Container 3 of 6.

Strainer and Auxiliary Fuel Assembly, Container 4 of 6.

800-GPM Mainline Pump, Container 5 of 6.

800-GPM Mainline Pump, Container 6 of 6.

Figure 2-2. 800-GPM mainline pump.

2-3

QM 5096

Previous Page

Previous Page