PART A - DIFFERENT TYPES OF PUMPS AND THEIR CHARACTERISTICS

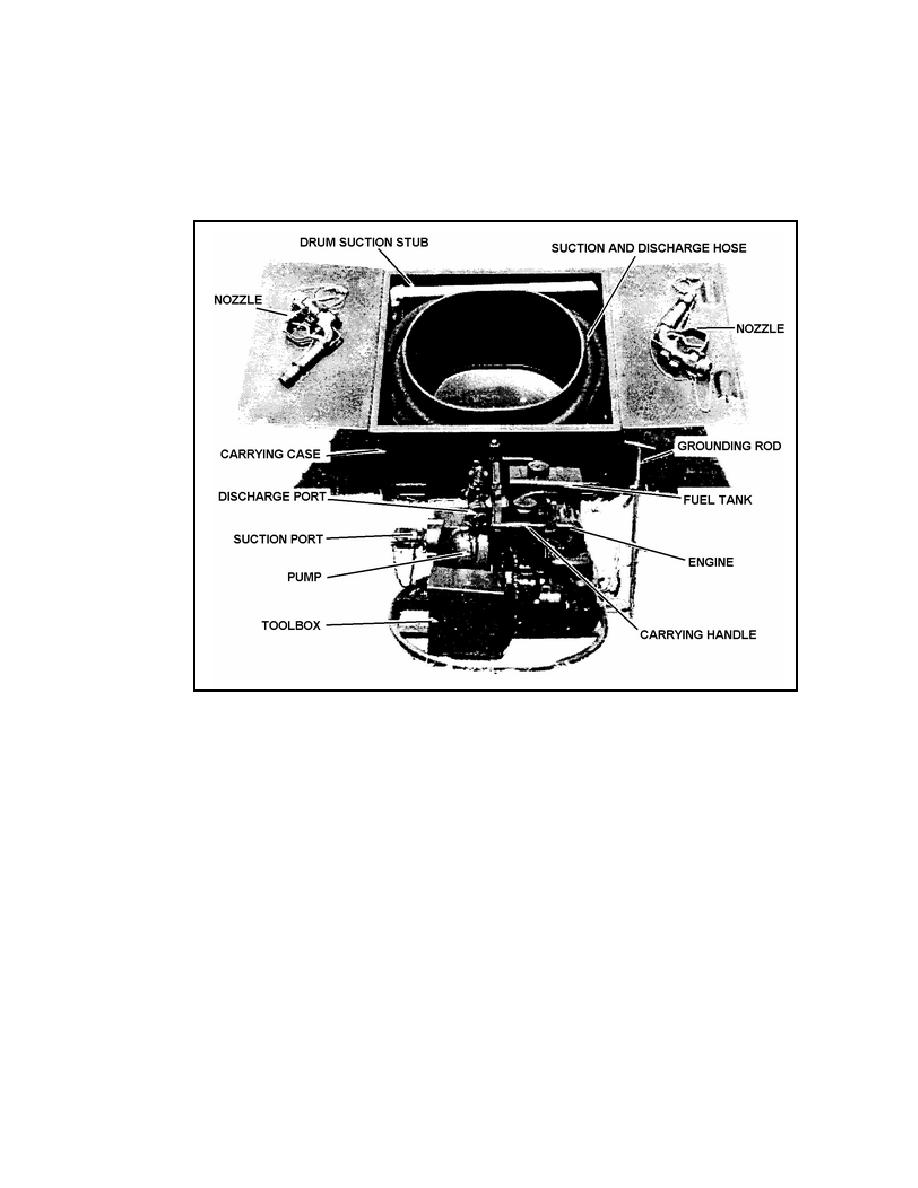

The 50 GPM pumping assembly (Figures 2-1) consists of a pump and engine assembly mounted on an oval

aluminum base. A one cylinder, four-cycle, air-cooled, gasoline engine is used to power the pump. The

pump is a self-priming centrifugal pump. The pump suction and discharge port has 1 1/2-inch cam locking

coupling adapters with dust caps.

Figures 2-1. The 50-GPM pumping assembly

The 100 GPM pumping assembly (Figures 2-2) is used as a component of the FARE system. An air cooled,

one cylinder, gasoline-driven, four cycle engine is used to power the pump. It develops 2 1/2 horsepower at

3,500 RPM. The 100-GPM pumping assembly is used to transfer fuel from storage tanks, tank cars, and

tank vehicles to smaller capacity containers.

2-2

QM 5098

Previous Page

Previous Page