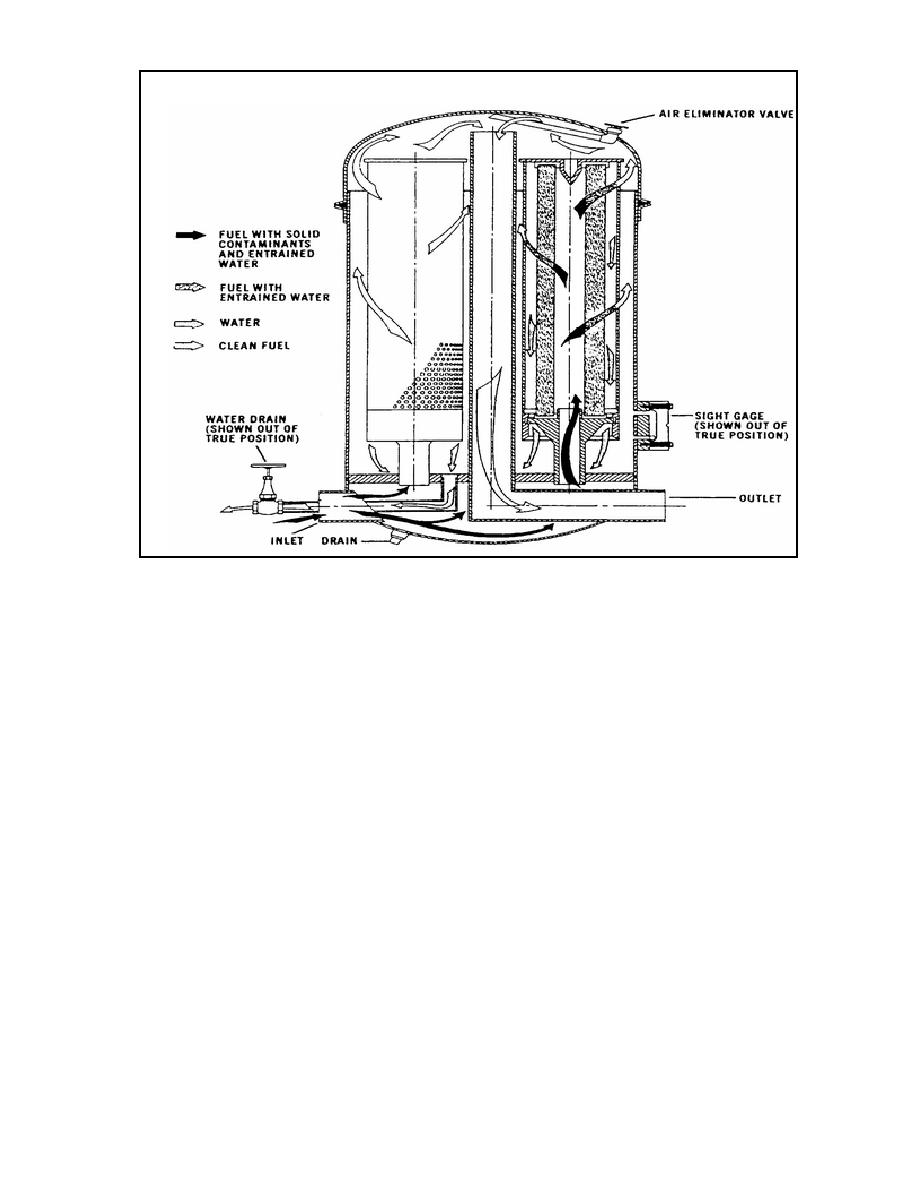

Figures 1-1. Typical flow through a filter/separator

PART B - SUPERVISING FILTER/SEPARATOR PMCS

Supervising Before Operation Maintenance.

Ensure a visual check is made for leaks and for loose or missing parts in the cover assembly and other

connections.

Ensure that all valves operate freely and do not leak. Ensure drain valves are in closed position.

Ensure the ground wire is connected properly and is not broken.

Ensure gaskets are in place and not leaking.

Ensure that fire extinguishers are accessible and in good working order.

Supervising During Operation Maintenance.

Ensure personnel check pressure gage reading to ensure pressure reading is below the red band on the

gage. If it is in the yellow band, change elements after the operation. (If in the red, stop operation.)

Ensure personnel check water level sight gage and drain water if necessary.

Ensure personnel check the filter/separator for leaks.

Supervising After-Operation Maintenance.

Ensure that personnel clean and store the equipment.

Ensure all dust caps and plugs are installed after the operation.

1-3

QM 5098

Previous Page

Previous Page