b. Pump station operation in parallel.

Parallel operation is not

normally used on petroleum pipelines but can be found in terminal operations

due to the capability to move high volumes of fuel. Parallel installation

increases flow rate capability without increasing head capacity. The lower

the head capacity, the closer together pump stations must be located;

therefore, the more pump stations required for a given length of pipeline.

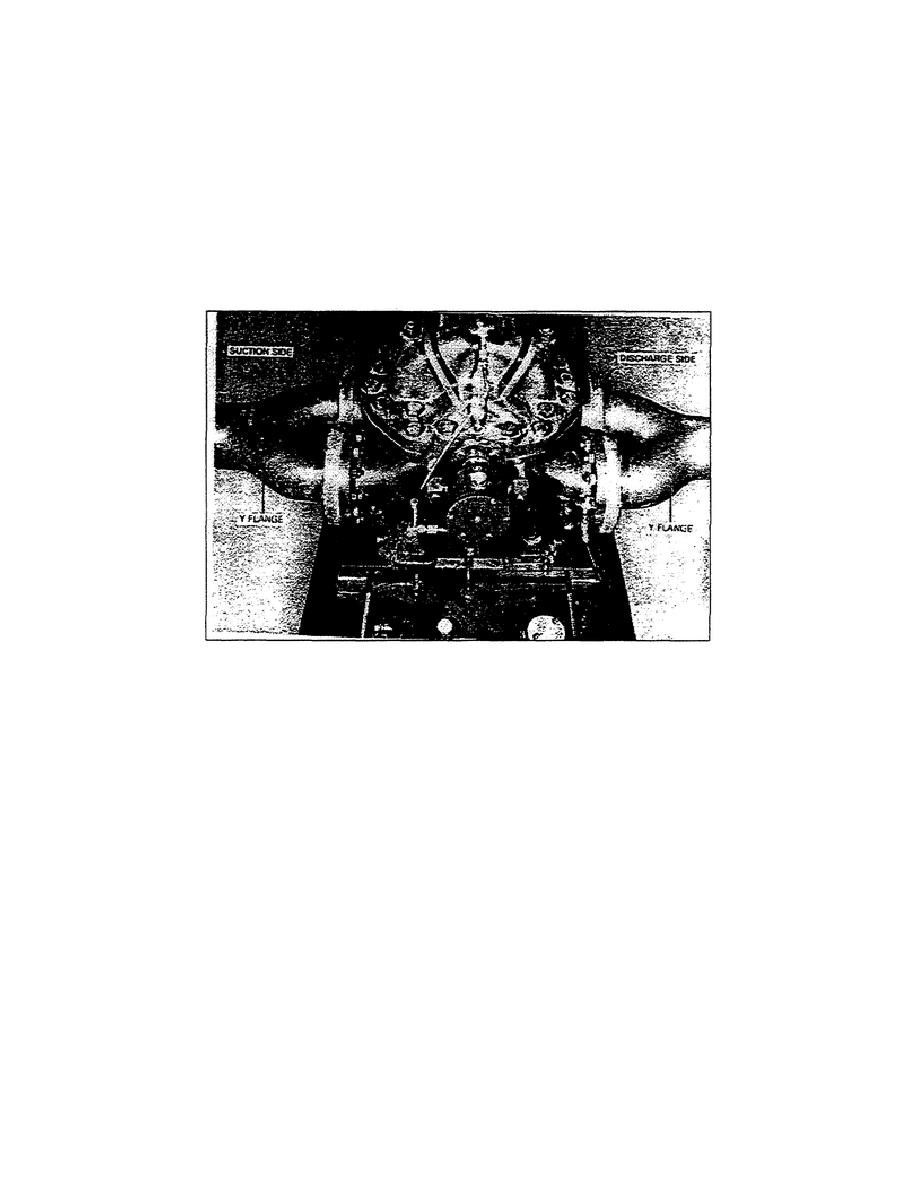

Only the 6-inch, two-stage pump can be placed in parallel operation.

Paralleling means that fuel flows through both stages at the same time.

This increases the volume and output of the pump.

The pump is put into

parallel by using Y flanges (Figure 4), which are attached the suction and

discharge side of the pump.

Figure 4.

The 6-inch, two-stage pump with stages in parallel

QM5201

10

Previous Page

Previous Page