INTRODUCTION

As a petroleum laboratory supervisor assigned to a petroleum laboratory, you are responsible for directing

the sampling and gaging tasks when performed by your laboratory technicians. The time spent in this lesson,

learning how to properly direct sampling and gaging operations, will ensure that your subordinates are

proficient and are aware of all the safety precautions needed to perform their mission.

PART A - SAMPLING AND GAGING EQUIPMENT VERIFICATION

Periodically and/or during scheduled laboratory inspections, you as the supervisor should ensure that the

proper equipment required for sampling and gaging operations is on hand and in good working condition.

Items that could be used to successfully perform sampling and gaging procedures, depending on the

particular laboratory mission, are listed as follows:

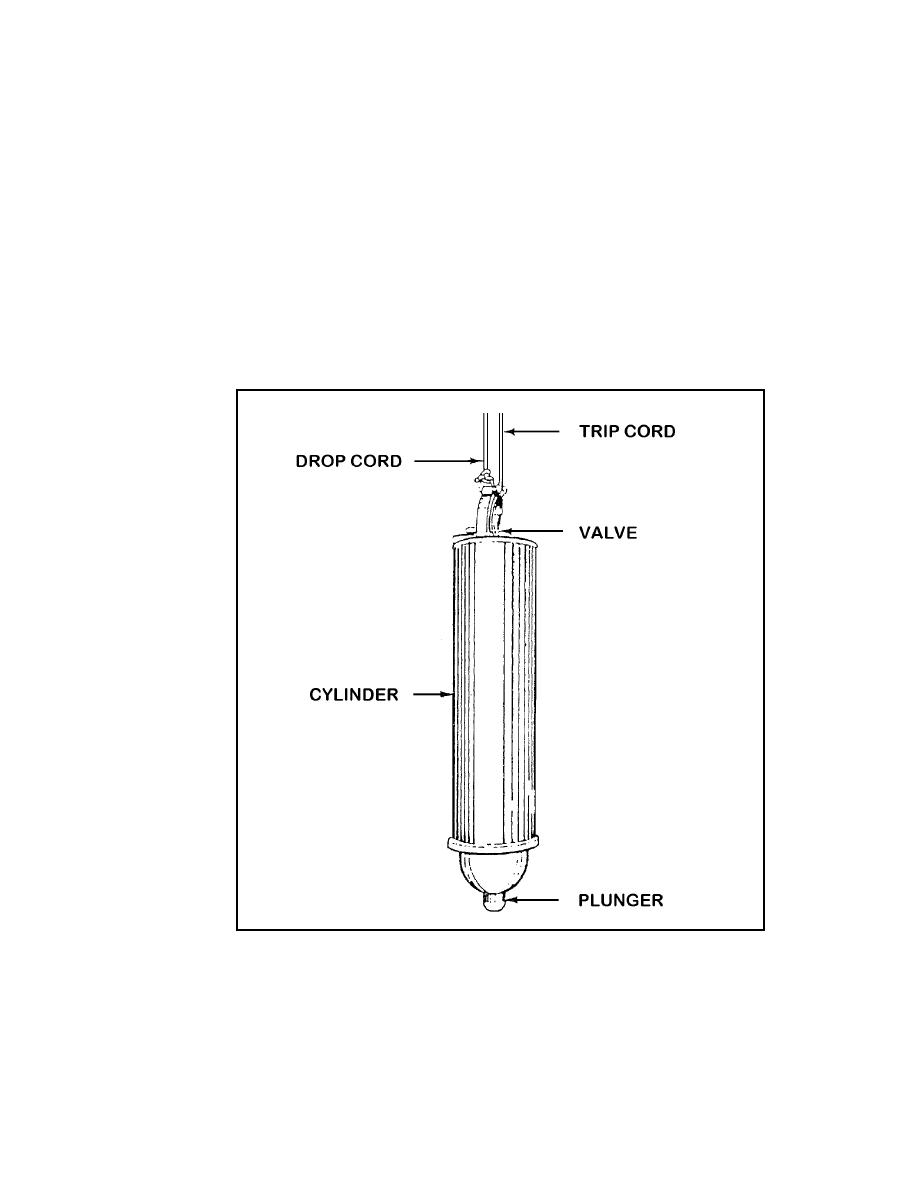

Bacon Bomb Sampler (refer to Fig. A-1) consists of a nickel-plated brass cylinder tapered at both ends

and fitted with an internal, plunger-type valve, and a drop cord. This sampler is used to take bottom

samples of liquid products of 2 psi or less RVP and samples of semi-liquid products.

Fig. 4-1. Bacon Bomb Thief

Drum Thief Sampler consists of a two-piece, plastic tube, 39 ,, inches long and 1 ,, inches at

maximum diameter. The tube is fitted with two finger rings at the upper end and three supporting legs at

the bottom. Both ends are tapered and have openings. This sampler is used to take samples of liquid

products of 12 psi or less RVP and samples of semi-liquid products.

Core Thief Sampler designed so that a sample can be obtained from the bottom ,, inch of the car or

tank. One type is lowered with valves open to permit the oil to flush through the container. When the

4-2

QM 5180

Previous Page

Previous Page