(4) Do not proceed until hypochlorite pump has been adjusted as

described in steps above. Otherwise, water that is unfit to drink will be

delivered to the storage tanks.

16. Your operation is now at the stage where you are ready to direct

potable water to the storage tanks.

If you are using new RO elements,

continue to direct the product water to waste for at least 30 minutes to

flush out the preservative. Have the operator perform the following:

a. Observe the reading of the in-line TDS meter.

If the reading is

under 100 ppm, use the portable TDS meter to measure the TDS from the

combined sample valve.

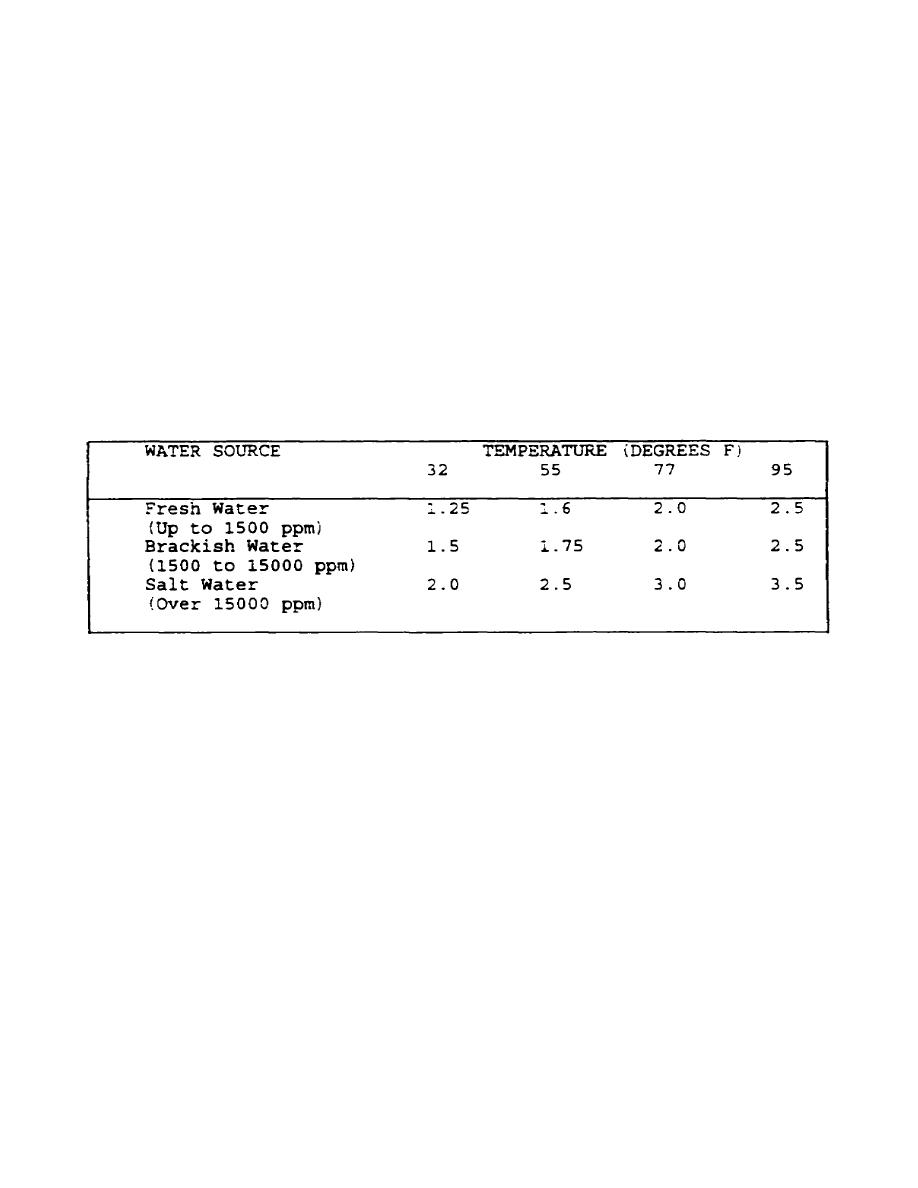

b. Table 1-6 presents the maximum product water TDS as a percentage of

the water source TDS.

Use the portable TDS meter to measure the water

source TDS.

Table 1-6.

Maximum Product TDS as a Percent of Water Source TDS

EXAMPLE:

Source TDS Sample - 25000 ppm at 95 degrees

Maximum TDS = 3.5 percent

25000 X 0.035 = 875 ppm

c. Have the soldier calculate the maximum product water TDS as shown in

the example.

If after 20 minutes the product water TDS has not dropped

below the calculated maximum, refer to RO elements troubleshooting.

d. Compare the actual measured product water TDS with the maximum TDS.

If less, proceed and direct the product water into the storage tanks by

inserting the product water hose in the middle tank and strapping it down.

Have the operator fill the 5 gallon plastic jug for use in the next start-

up.

Set the 5 gallon jug filled with product water in the corner of the

van.

17. Since water is being pumped into the product tanks, have an operator

check the product water for the proper chlorine

1-13

QM4911

Previous Page

Previous Page