15. The next step is to have the crew proceed with the final chemical

system setup. Make sure that the crewmembers wear a protective shield and

gloves when handling chemicals.

Ensure that the correct procedures are

followed.

a. Have the operator start with the final polyelectrolyte setup.

If

polyelectrolyte is not being used, fill the polyelectrolyte tank half full

with product water and proceed to "Sequestrant Setup". The operator should

perform the following:

(1) Add an additional 28 oz of polyelectrolyte to the polyelectrolyte

tank. Partially close the product shut-off valve to provide back pressure

no greater than 20 psig. Open fully when the chemical tanks are filled.

(2) Use the product utility hose to fill the tank with product water.

Vigorously mix with mixing paddle for two minutes. Visually make sure all

polyelectrolyte is in solution.

(3) The normal fill is 48 oz of polyelectrolyte in a full tank (12

gallons) of water which equals to 4 oz per gallon of water.

b. Have the operator move to the sequestrant setup.

Sequestrant

containers and chemical bottles are identified by a square symbol.

The

operator should perform the following:

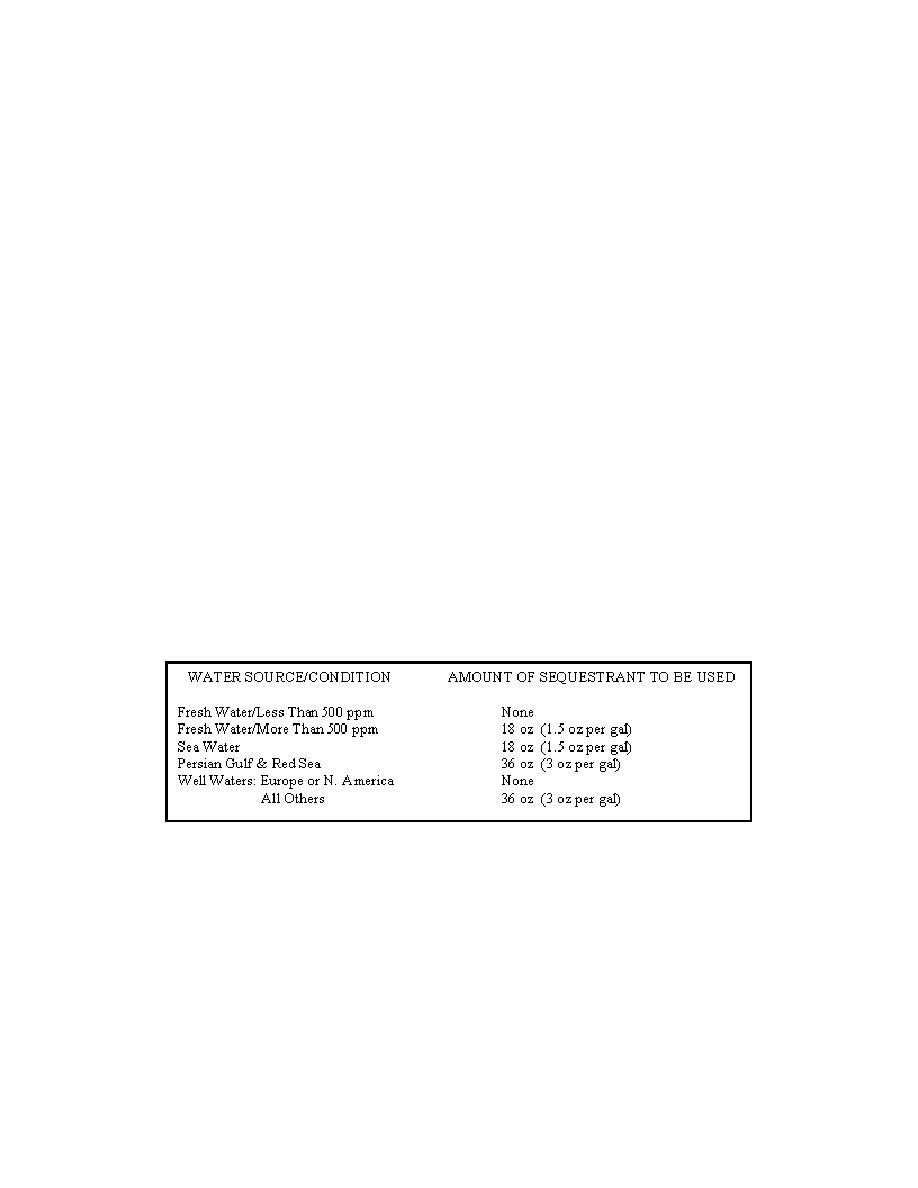

(1) Fill sequestrant tank half full with product water, using product

utility hose. The operator determines how much sequestrant should be used

based on the TDS, type of source, and adds it to the tank (see Table 1-4).

Table 1-4.

Sequestrant Concentration

(2) If sequestrant is added, also add one large 2 lb bag of

bisulfite. Fill tank to full level (number 12 on scale) with product water

and vigorously mix with mixing paddle for two minutes.

By visual

observation, make sure all sequestrant is in solution. The operator should

use caution when mixing to avoid hitting fittings and switches in tank.

1-11

QM4911

Previous Page

Previous Page