bottom and are read upward to 1 inch as the last whole number on the top. The outage bob has a flat

nose and is made of nonsparking metal.

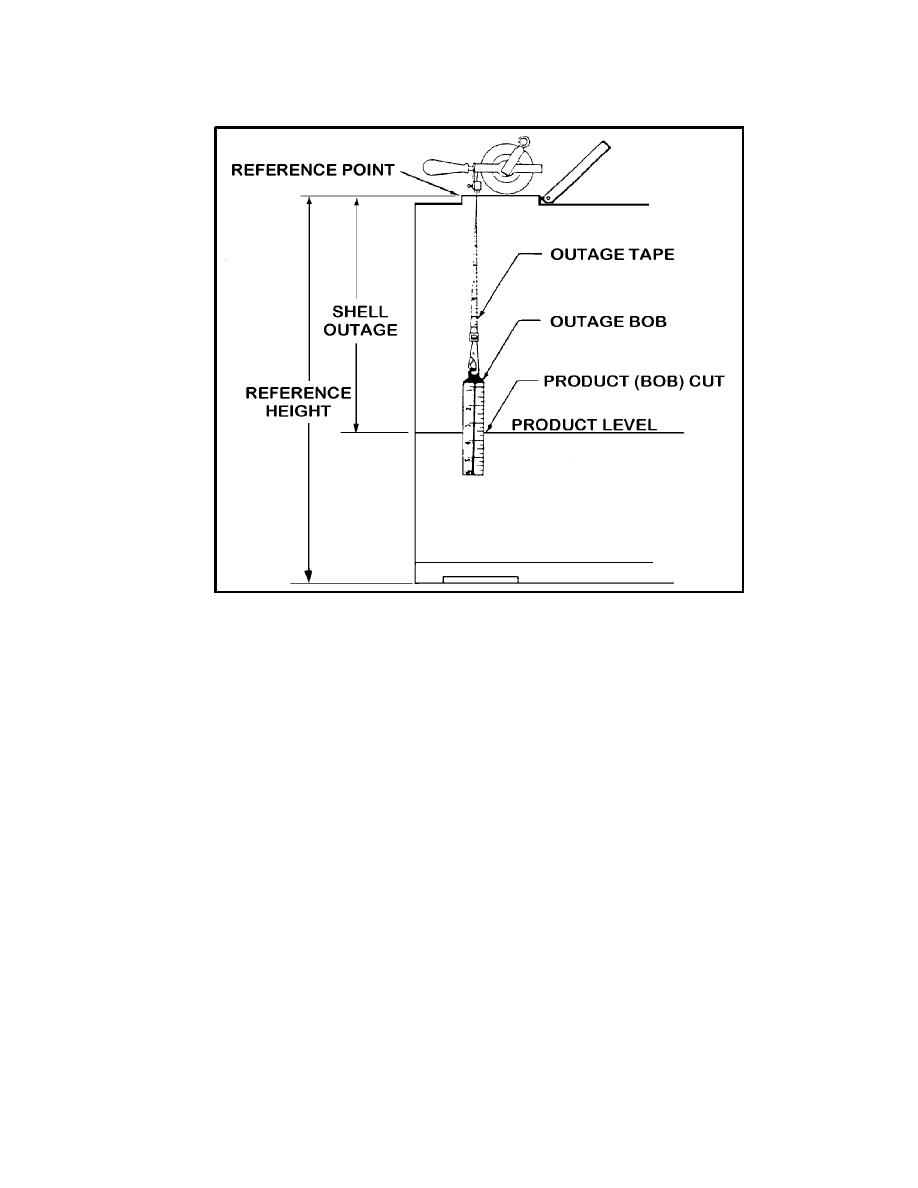

Figure 6-8. Outage tape and bob.

General Precautions. General precautions for gaging are as follows:

Remove gaging device housing by unscrewing it carefully and slowly. If pressure exists, unscrew

housing two or three threads to relieve pressure. Do not unscrew housing completely or release gage-

tube lock with head or body over it as high pressure may cause the gage tube to rise rapidly.

Whenever there is a gage-tube safety latch, tighten the packing nut to prevent leakage and replace the

gaging device housing.

Use care in operating all valves and removing and replacing their plugs. Use open-end or socket

wrenches on the plugs, and do not apply much force on valves with broken stems.

If there is any pressure or sound of escaping vapor, the pressure must be relieved.

Be sure all loading connections are tight before operations are started. After shutting the supply valves,

release pressure in the line before disconnecting.

To test for leaks, spread soapy water or light mineral oil on the suspected part to aid in verification.

Never test with a flame.

If excess-flow valves close, it is necessary to close the operating valves to allow pressure to equalize.

Carefully regulate the rate of flow to prohibit an excessive rate of flow.

Innage Method of Gaging. Gaging procedures for atmospheric and other non-pressure tanks using

the innage tape and bob are as follows:

Raise the appropriate hatch cover and locate the reference point.

Apply water-indicating paste to the bob and product-indicating paste to the tape at the expected level of

the product in the tank. Apply the paste thinly and to the graduated side of the tape.

The ungraduated side of the tape is held in contact with the metal rim of the gaging hatch at the

reference point as the tape is lowered into the tank.

QM 5097

6-8

Previous Page

Previous Page