PART B - CHECKING PROCEDURES USED TO OBTAIN THE

TEMPERATURE OF PETROLEUM PRODUCTS

Temperature Measurement. Because the volume of petroleum products increases or decreases in

direct proportion to temperature increase and decrease, accurate measurement of the temperature of a

product must be taken at the time of gaging. The measured quantity must be corrected to the standard

temperature of 60F for volumes over 3,500 gallons. When gaging large quantities, take temperature

readings at various levels and average them to determine the true average temperature of the product.

Table 3-1 of FM 10-67-1 (Concepts and Equipment of Petroleum Operations) (Figure 6-4) shows the number

of readings necessary and the levels at which tank thermometers should be placed.

Minimum Number of

Depth of Product

Temperature Measurements

Measurement Levels

More than 15 feet

3

3 feet below top surface of product,

middle of product, and 3 feet above

the bottom

10 -15 feet

2

3 feet below top surface of product,

and 3 feet above the bottom

Less than 10 feet

1

Middle of product

Figure 6-4. Petroleum product temperature measurements (FM 10-67-1, Table 3-1 extract).

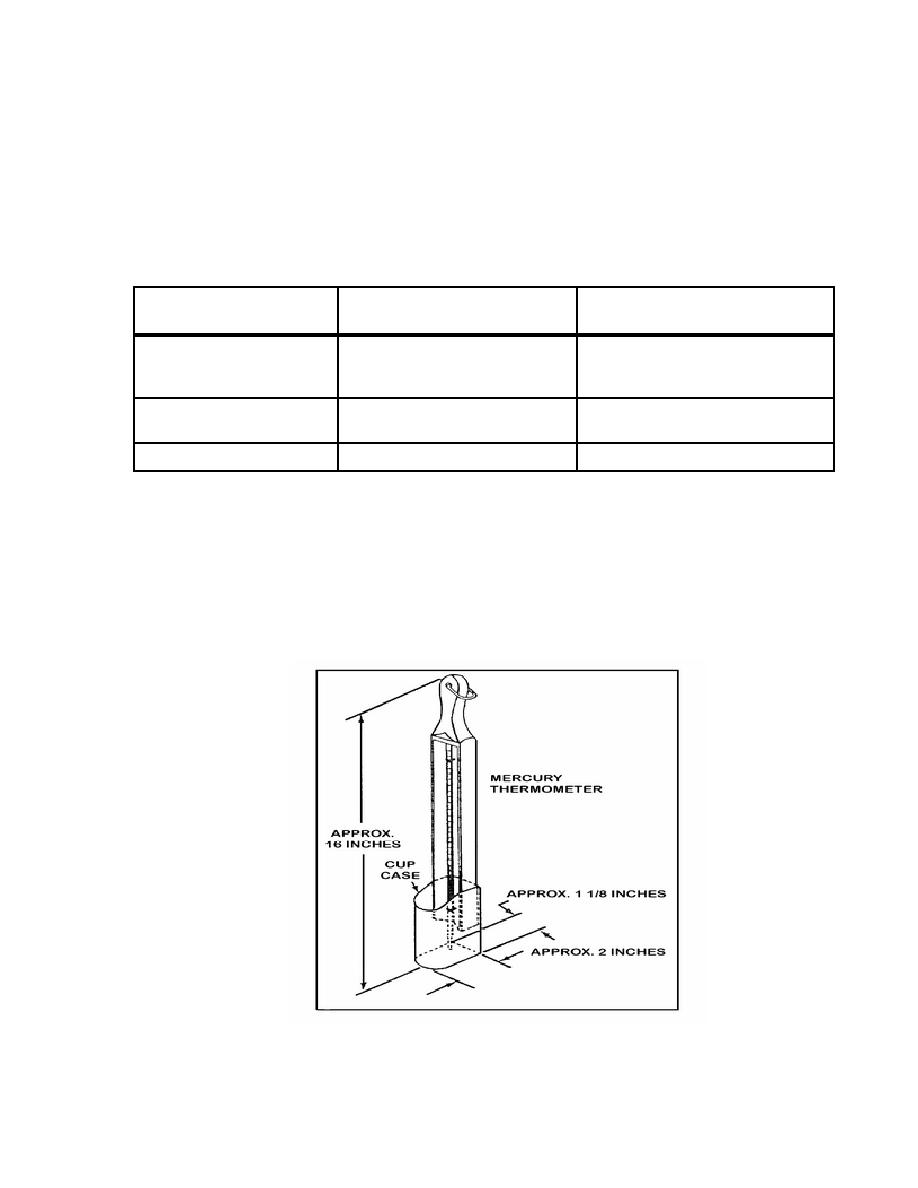

Measuring Instrument. The cup-case thermometer (Figure 6-5) is used to measure the temperature of

a product in storage tanks. The thermometer is attached to a hardwood backing with the base of the mercury

column extending into the cup case. The cup case, when filled with liquid under measurement, minimizes

fluctuation of the reading when the thermometer is suddenly withdrawn from the tank. The minimum

immersion time for the cup-case thermometer in various petroleum products is given in Table 3-2 of FM 10-

67-1 (Figure 6-6). To avoid the long immersion time required for measuring the temperature of heavy fuel

oils, it may be practical to leave thermometers suspended in the tanks at all times.

Figure 6-5. Cup-case thermometer.

6-5

QM 5097

Previous Page

Previous Page