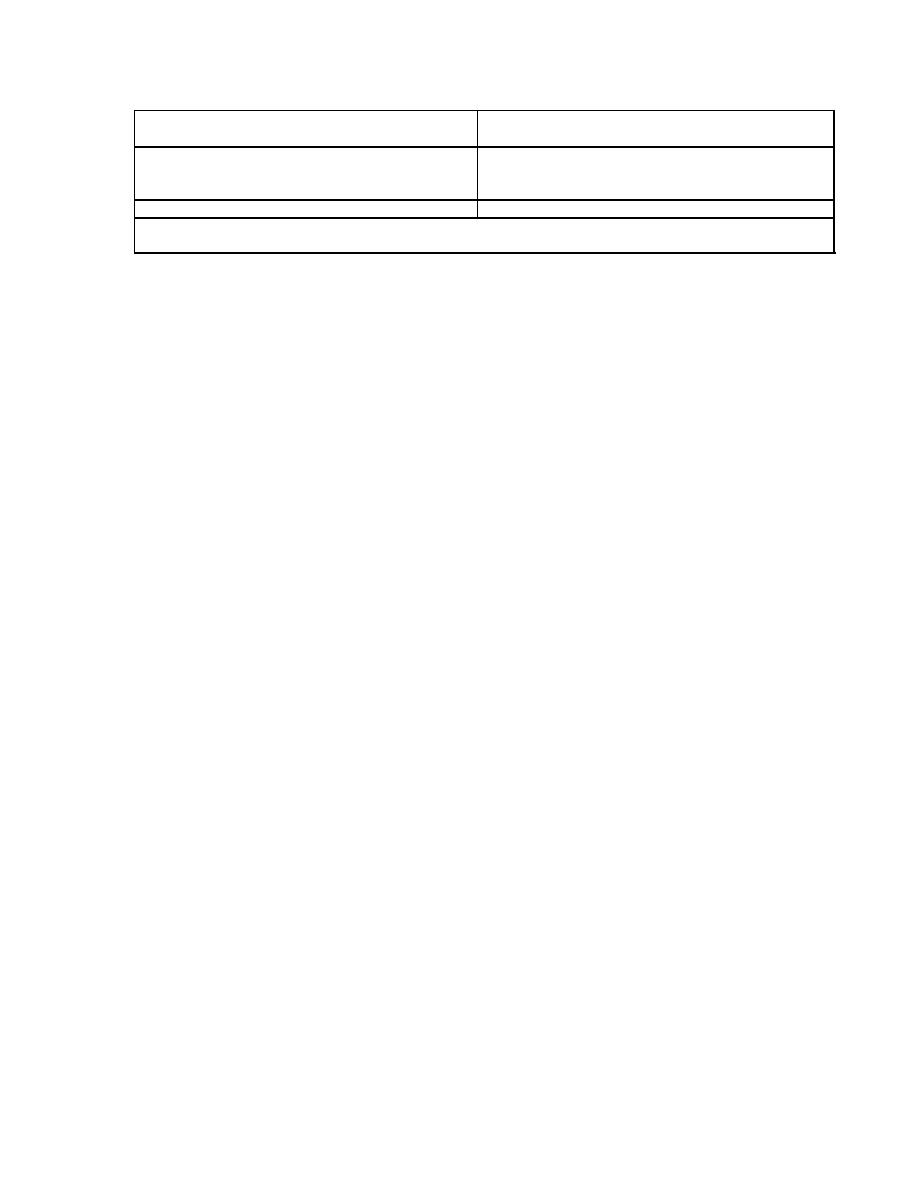

TIME

PRODUCT

(MINUTES)

Automotive gasoline (MOGAS), aviation

5

gasoline (AVGAS), kerosene, diesel fuel, jet fuel,

and grades 1 and 2 burner fuel oil

Grades 4, 5, 6, and Navy Special burner fuel oil

15

NOTE: This conforms to Table IV, Minimum Immersion Time for Cup-Case Assembly, API Standard

2543, ASTM Designation D 1086. Product listings are not comprehensive.

Figure 6-6. Minimum immersion times for the cup-case thermometer (FM 10-67-1, Table 3-2 extract).

Measuring Procedures. To measure the temperature of petroleum products in storage tanks, the

following procedures are used:

The thermometers are inspected for separation of the mercury column, and any faulty thermometers are

replaced. Separation of the mercury column results in incorrect readings. Each thermometer is checked

for accuracy by comparing the readings of a number of thermometers exposed to atmospheric

temperature at the same time and location. Any thermometer that has a reading deviation from the other

readings by more than 0.5F is replaced.

The cup case is attached to the end of a gage tape or suitable cord.

The thermometer is then lowered to the required product level and allowed to remain at this level at least

as long as the minimum time specified in Table 3-2 of FM 10-67-1 (Figure 6-6).

The thermometer is then withdrawn and read immediately with the cup sheltered below the edge of the

hatch to minimize any change of reading that may be caused by wind or atmospheric temperature. The

cup must be full when withdrawn, and the product must not be spilled from the cap when taking a

reading. As quickly as accuracy will permit, the temperature is recorded to the nearest 0.5F.

When readings are taken at more than one level, all readings are added and divided by the number of

readings in order to obtain the true average temperature of the product. For example, assume a tank

had 20 feet of product in it. You would take recordings at 3 feet, 12 feet, and 21 feet, according to Table

3-1 of FM 10-67-1 (Figure 6-4). Assume that readings of 82 F, 81 F, and 80F were obtained. Add

these readings and divide by three to get an average temperature.

PART C - CHECKING GAGING PROCEDURES

Accurate gage readings, temperature API gravity, and the volume of bottom sediment and water (BS&W) are

necessary to calculate the net volume of petroleum at the standard temperature of 60F. Gages are

determined through specified gaging hatches in tanks, ships, barges, tank cars, and tank trucks. There are

two basic types of procedures for obtaining gages: innage and outage. Normally, outage gage is used for

vessels and railcars, and innage gage is used for storage tanks. Bulk petroleum products are often handled

many times before they are used. Throughout this handling, they must be rigidly accounted for, and accurate

quantity records must be maintained at all times. For accountability purposes, products must be gaged

periodically to determine the quantity of products on hand, verify of quantities received or issued, detecting

leaks or unauthorized withdrawals, determine presence and amount of BS&W, and determine the terminal

capacity for receiving shipments. Accounting for all receipts, issues, transfers, and operational gains and

losses of bulk petroleum products is a major responsibility of the terminal accountable officer.

Gaging Terms. The following gaging terms are used:

Innage. The depth (height or volume) of product in a tank measured or gaged from the surface of the

product to the tank bottom.

Outage (Ullage). A measurement of the free space above the surface of the product extending to the

reference mark.

Reference Mark. A horizontal line put in the rim of the gaging hatch representing a fixed point from

which measurements are made.

Datum Plate. A level metal plate at the tank bottom and directly under the reference mark. This plate

provides a smooth, level surface for the innage bob to rest upon.

QM 5097

6-6

Previous Page

Previous Page