Site Preparation. All sticks, stones, and debris should be cleared from the area. To prevent fires, clear

dry grass, leaves, and brush away from the pumping assembly. In some cases, engineer personnel prepare

the site.

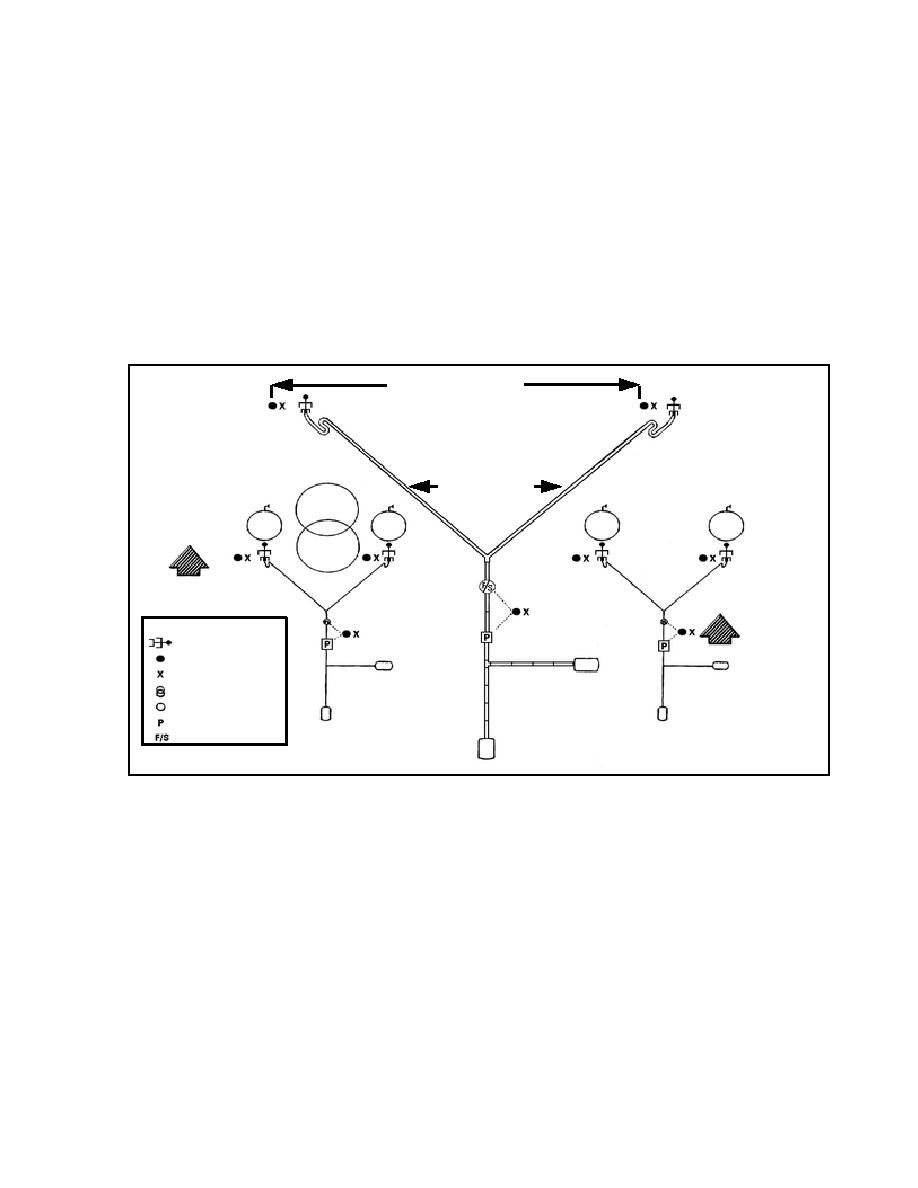

Layout. Once all equipment is on-site, lay out the FARE system in the way that is best for the specific

situation. Tailor the layout to avoid obstacles, take advantage of terrain features, achieve maximum

dispersion, and operate with a restricted amount of space. The only mandatory feature of the FARE system

is the spacing between the aircraft (Figure 5-1). The suggested sequence of setup is as follows.

Position pump and filter/separator.

Ground pump and filter/separator.

Assemble discharge hose.

Assemble dispensing points.

Connect to two 500-gallon collapsible drums.

Position fire extinguishers.

Approximately 100 Feet

Discharge Hose

Wind

LEGEND

CCR Nozzle

Wind

Ground Rod

Fire Extinguisher

Refueling OH-6, OH-58,

CH-47

AH-1, UH-60A, AH-64, and

Single Rotor Aircraft

UH-1 Single Rotor Aircraft

Pump

Refueling CH-47

Filter/Separator

or CH-54 Aircraft

Figure 5-1. Typical FARE layout.

PART C - QUALITY SURVEILLANCE

The quality and cleanliness of turbine fuel are vital to the safety of turbine-engine-powered aircraft. Turbine

engines have more stringent cleanliness requirements than do reciprocating engines. Because turbine

engines have high fuel consumption rates, contaminants accumulate in them rapidly. Turbine engine filters

cannot remove fine sediment, excess amounts of sediment, or water from the fuel. Separating the

contaminants from JP-5 and JP-8 is time-consuming and further complicated by their high viscosity and

specific gravity. Any unit or organization that has military-owned aviation fuel in its physical possession is

responsible for establishing and maintaining an adequate quality surveillance program. Each person

involved in aircraft refueling is responsible for ensuring that the fuel pumped into an aircraft is clean, bright,

on specification, and does not contain any free water or sediment.

Quality surveillance testing and sampling are used to find common contamination hazards. The hazards

that may affect aircraft are sediment, water, microbiological growth, and commingled fuel. Since each

5-3

QM 5095

Previous Page

Previous Page